The hydrogen industry relies heavily on steam methane reforming and electrolysis for hydrogen production. These traditional methods require a lot of energy and often lead to substantial CO2 emissions, making them less sustainable. The hydrogen companies are shifting their focus toward another innovative way to produce hydrogen that goes easy on the environment and is cost-effective.

Hydrogen production from biomass and waste offers a sustainable alternative. It reduces reliance on fossil fuels and cuts greenhouse gas emissions. This method repurposes organic waste, turning it into a valuable energy source.

Compared to traditional methods like steam methane reforming, which is energy-intensive and emits CO2, biomass, and waste conversion are more eco-friendly and cost-effective, leveraging abundant and renewable resources.

Specific processes like SPEG can convert waste materials directly into hydrogen, minimizing the energy input and carbon footprint associated with hydrogen production.

This article introduces five handpicked and promising startups working on hydrogen production from biomass and waste. It further discusses their technologies, their impact, and what makes their technology different from current innovation trends.

Explore the Hydrogen Startup Ecosystem via our detailed Report. Fill out the form to get the report:

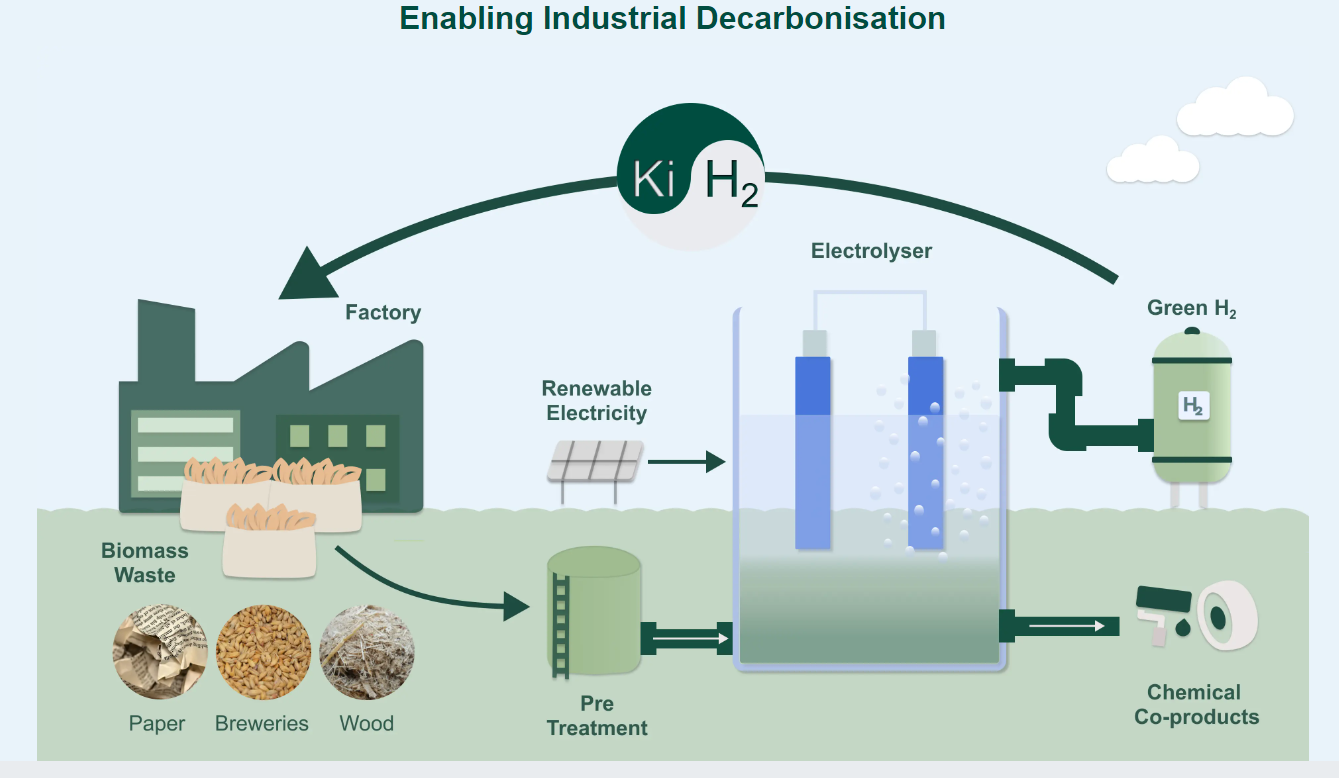

1. Ki Hydrogen Revolutionizing Green Hydrogen with Biomass Electrolysis

| Founding Year | 2022 |

| Headquarters | London, UK |

| Total Funding Amount | Unknown |

| Last Funding Round | Pre-seed/$1.1 Million |

| Website | https://ki-hydrogen.com/ |

Generating one kilogram of green hydrogen via water electrolysis requires electricity equal to that used by an average UK household for one week. Energy consumption and expenses make up 70% of the total cost of hydrogen.

Also, 99% of Hydrogen produced today is derived from fossil fuels. 94 Million tonnes of hydrogen produced annually generates over 830-900 million tonnes of CO2.

Ki Hydrogen uses biomass electrolysis technology to produce green hydrogen from biomass waste.

Their technology reduces the required energy by up to 75% compared to hydrogen production methods like water electrolysis. This patented solution extracts value from waste biomass through a direct electrolysis process. The by-product produced by this method can also be sold. With this approach, prices of green hydrogen can be brought to $2/kg.

The startup’s founding team includes Koji Muto as CEO, Michael Stanton as CTO, and Carl Banbury as COO. Muto holds an MBA from London Business School and has industrial experience developing the UK’s largest hydrogen project worth $800 million as a senior engineer at ExxonMobil.

In Nov 2023, it raised $1.1 Million in a pre-seed funding round.

2. Hydrogen Refinery Ltd (H2R) Producing Drop-in Fuels Using Plasma Electrolysis System (PES)

| Founding Year | 2021 |

| Headquarters | London, England |

| Total Funding Amount | Unknown |

| Last Funding Round | Unknown |

| Website | www.h2refinery.co.uk |

Waste processing through landfill or incineration significantly contributes to emissions, producing 1 tonne of CO2 for every tonne processed and accounting for 4% of global climate emissions. With waste projected to grow and recycling rates low, these methods exacerbate climate change.

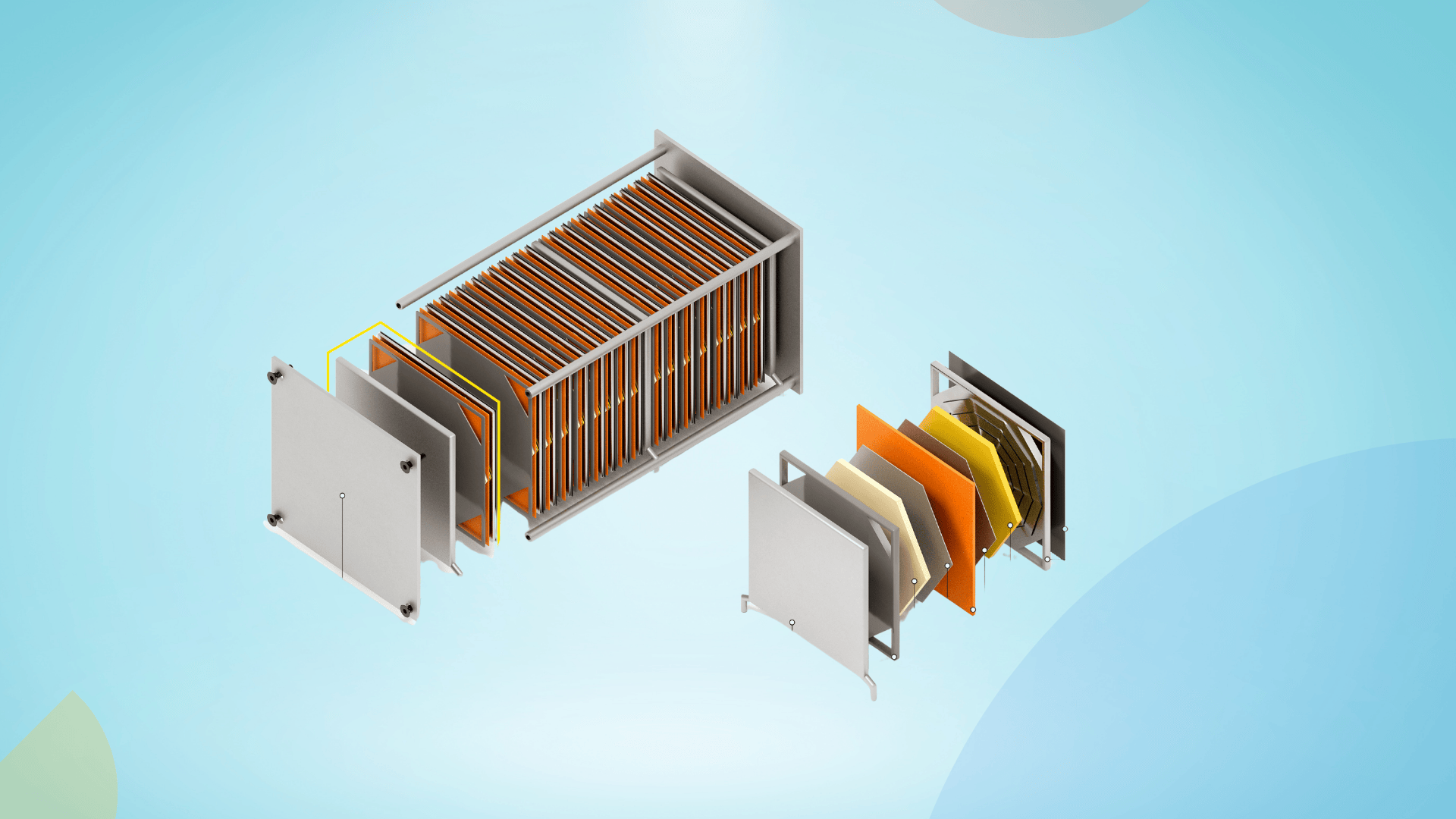

H2R uses military-developed patent-protected Plasma Electrolysis System (PES) technology to create hydrogen and syngas from waste.

The PES technology uses low-energy microwaves to create a swirling plasma. Unlike other plasma-based methods, PES doesn’t involve special materials or membranes. The swirling plasma breaks down any hydrocarbon (like plastics) introduced into it, producing pure hydrogen gas. If the input material is waste, like non-recyclable plastics ground up, all the carbon and other impurities in the plastic come out as carbon soot. However, to reduce the amount of soot produced, carbon dioxide is added to the process, which creates a synthesis gas (syngas) output containing carbon monoxide.

The PES process is carbon-negative because it avoids the methane and carbon emissions associated with conventional waste processing methods, such as incineration and landfills.

The startup is moving forward under the leadership of CEO, CTO, and Co-founder Stephen Voller C.Eng. He is the inventor of carbon-ion technology, which uses nanomaterials to enhance supercapacitors, and the author of over 100 patents.

Intrigued by these innovative startups?

Green Hydrogen Startup Report

Download Report3. SGH2 Energy Producing Greener Than Green Hydrogen with SPEG

| Founding Year | 2020 |

| Headquarter | Washington DC, Southern US |

| Total Funding Amount | $5 Million |

| Last Funding Round | Debt Financing |

| Website | https://www.sgh2energy.com |

Although renewable, traditional electrolysis for green hydrogen production is costly and demands substantial energy and water resources. It requires 62 KWh to produce 1 kg of hydrogen from 8 gallons of deionized water. Also, Blue, gray, and brown hydrogen producers either use fossil fuels (natural gas or coal) or low-temperature gasification (<2000º C) to produce dirty syngas with low hydrogen and toxic tars.

SGH2’s new process, “greener than green hydrogen,” is trying to overcome these challenges. The startup uses patented Solena Plasma Enhanced Gasification (SPEG) technology to produce green hydrogen from plastics, rubber, and textile waste. SGH2 projects production costs of US$2 per kg of green hydrogen.

Lawrence Berkeley National Lab reveals that the SGH2 process reduces CO2 emissions by 23 to 31 tons per ton of hydrogen, surpassing other green hydrogen methods by 13 to 19 tons. Also, it is 5 to 7 times cheaper than any other green hydrogen.

The team behind SGH2 includes CEO Dr. Robert T. Do, who is also the inventor of SGH2 Hydrogen Production technology. Dr. Do holds graduate degrees in BioPhysics and Medicine from Georgetown University and attended an Executive MBA Program at Harvard University Business School.

The startup last raised $5M in funding in May 2022.

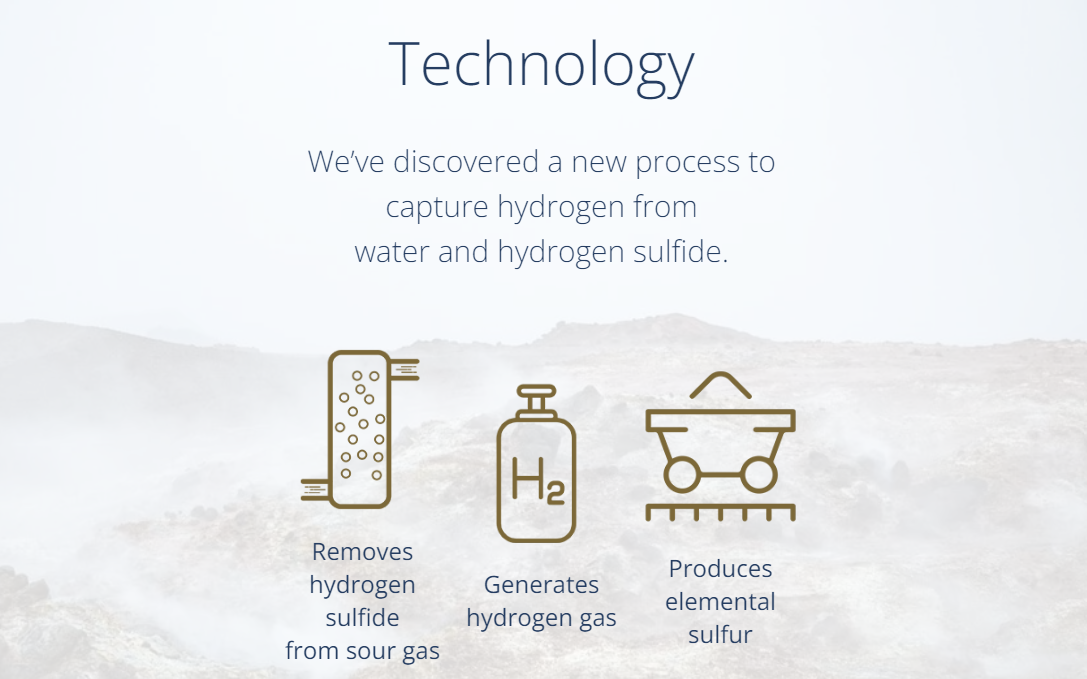

4. Thiozen Generating Low Emission Hydrogen with Sour Gas

| Founding Year | 2020 |

| Headquarters | Beverly, Massachusetts |

| Total Funding Amount | $5 Million |

| Last Funding Round | Grant |

| Website | https://thiozen.com/ |

Existing methods to produce hydrogen contribute to over 2% of all greenhouse gas emissions and emit harmful gases that affect the habitats near hydrogen plants.

Thiozen, a startup founded at MIT, addresses critical challenges in the hydrogen industry by developing a novel chemical process to generate low-emission hydrogen from sour gases. The company’s technology claims to reduce greenhouse gas emissions from sour gas processing and hydrogen gas production, contributing to the energy transition and a more sustainable future.

It produces hydrogen from a high-volume industrial waste stream and water, avoiding the large carbon footprint of traditional hydrogen production methods.

This patented chemical cycle reduces global greenhouse gas emissions by more than 300 million metric tons annually. It also improves air quality and respiratory health in communities near the current waste—and gas-based hydrogen infrastructure.

Its CEO, Dr. Ryan Gillis, has a Ph.D. in Chemical Engineering from MIT.

Thiozen received a Grant of $1.2 Million in Feb 2024.

Energy Storage Industry Trends 2025 Report

Download Report5. PuriFire Labs Transforming Wastewater into Hydrogen And Methanol

| Founding Year | 2019 |

| Headquarters | Cambridge, UK |

| Total Funding Amount | £100K |

| Last Funding Round | Pre-seed |

| Website | https://purifirelabs.com/ |

While effective, traditional electrolysis requires large amounts of clean water and electricity, which can be scarce in certain regions. Additionally, relying solely on specific waste streams might limit green hydrogen production scalability and overall environmental impact.

PuriFire Labs is tackling these challenges with a novel hydrothermal treatment process that transforms wastewater into green hydrogen and carbon-neutral methanol. This technology aims to decarbonize the shipping and chemical sectors to promote a low-carbon economy.

The process produces green hydrogen and carbon dioxide in proprietary reactors and upgrades these outputs into carbon-neutral methanol through catalytic synthesis. It does not require a compressor or electrolyzers.

The system’s ability to integrate waste heat from industrial sites and farms adds another layer of efficiency, maximizing resource utilization. As a result, this technology offers a scalable and environmentally friendly solution for producing green hydrogen.

Neel Shah, the CEO, co-founded the startup and holds an MBA from the International Business School INSEAD.

PuriFire Labs has raised funding in three rounds. Its latest funding was raised in Feb 2023 from a Pre-Seed round.

Partner with cutting-edge startups to tackle your industry’s toughest challenges and stay on top of the competition.

Learn how GreyB can help you discover similar ventures that perfectly fit your needs.

How Can We Help You?

We support industry-leading R&D and Innovation professionals through complex problems. Describe your challenge, and let us bring clarity and expertise.