Replicating the benefits of human milk oligosaccharides (HMOs) in infant formula is costly and has limited scalability. Traditional fermentation struggles with high expenses. Safety concerns over synthetic alternatives further complicate the development of practical solutions.

Advancements in HMO production are beginning to address these roadblocks. For instance, Genechem Inc.’s new method for producing 3-fucosyllactose (3-FL) uses modified yeast to cut costs, improve efficiency, and enable large-scale production. This is just one example of how ongoing research is reshaping the industry.

Companies are actively working to refine production methods, overcome cost barriers, and bring formulas closer to breast milk’s composition.

GreyB’s research explores these market trends, emerging innovations, leading companies, and the key solutions driving the future of infant nutrition.

Get access to our upcoming report

Fill the form to sign up

HMO Market Trends: Growth, Challenges, and Regulatory Advancements

The HMO market was valued at $264.20 million in 2023 and is projected to grow at a 13.8% CAGR through 2030. This growth is driven by rising awareness of infant nutrition, advancements in production technologies, and evolving regulations, for instance-

China’s approval of 2’-fucosyllactose (2’-FL) and Lacto-N-neotetraose (LNnT) has opened up a new market for HMO-enriched products. Companies are eager to enter this growing market, with Nestlé already launching HMO-enriched formulas to meet the demand from Chinese consumers. This shows the rising importance of China as a new market for HMO products.

In North America, FDA approvals for more HMOs have encouraged companies to invest in fermentation-based production. This allows for large-scale manufacturing and reduces production costs, making it easier to meet the rising demand for HMO-enriched formulas.

As the market grows, the challenge remains to integrate HMOs into formulas while maintaining quality and accessibility. The following section explores companies addressing these challenges and advancing HMO production.

Key Players Driving HMO Innovations

Leading HMO market players like Glycom, Chr. Hansen, Kyowa Hakko Europe, FrieslandCampina, and BASF are driving industry growth. They are shaping the market through strategic partnerships, expanded production, and innovative HMO development.

Patent tracking and competitor analysis are crucial to spot emerging innovations in the industry. Yet, the process is challenging and time-intensive.

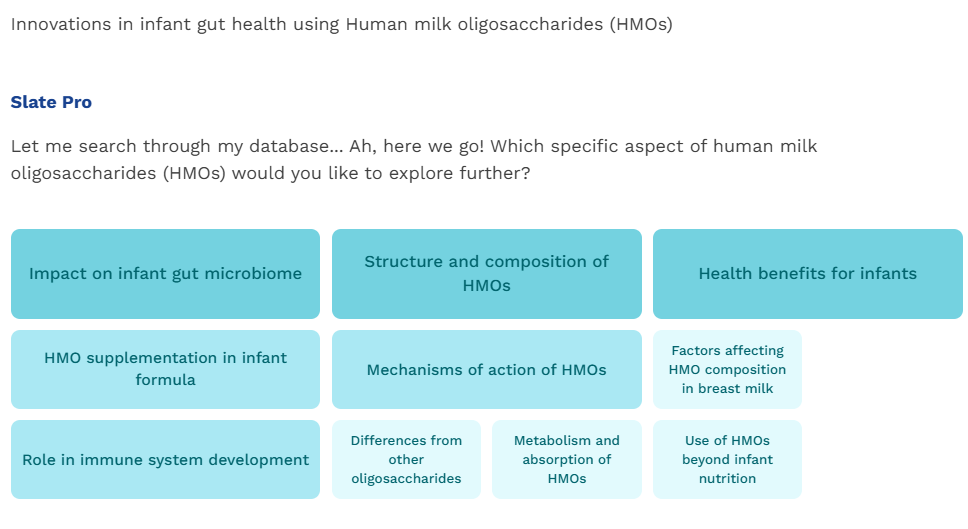

GreyB tracked the recent patents and developments in HMO production using its proprietary R&D research workspace, Slate Pro. The research provides insights into key company advancements in HMO innovations.

See what your competitors are doing in HMO innovation and production. Get these insights and regular industry updates faster with Slate.

BASF: Reverse Osmosis for High-Purity HMO Production

BASF’s innovative reverse osmosis process enhances the concentration of HMOs like 2’-FL by minimizing energy consumption and preserving product quality.

This method achieves high osmotic pressures without thermal degradation by utilizing dairy reverse osmosis membranes, ensuring a consistent, high-quality HMO product. Compared to traditional thermal evaporation, reverse osmosis reduces energy consumption, lowers costs, and enhances efficiency while preserving HMO integrity. This results in higher yields, minimal product loss, and superior-quality spray-dried HMO powder, making large-scale production more feasible. Additionally, with reduced energy use and a smaller environmental footprint, this process aligns with sustainability goals while delivering affordable, high-quality HMO-enriched formulas to meet growing market demand.

FrieslandCampina: Wet Blending for a More Efficient Infant Formula Process

FrieslandCampina has developed a unique oligosaccharide blend that combines HMOs like 2’-FL with galacto-oligosaccharides (GOS), fructo-oligosaccharides (FOS), and polydextrose (PDX).

This wet blending process removes the need for separate drying steps. This saves energy and simplifies production. The integrated blend enhances microbial stability. It promotes a healthy intestinal microbiome and supports infant nutrition. This efficient and sustainable approach helps R&D teams optimize formulations while maintaining high-quality nutritional standards.

Kyowa Hakko: Enzyme Engineering for Cost-Effective HMO Synthesis

Kyowa Hakko has introduced a modified protein with enhanced α1,2-fucosyltransferase activity and developed a method to produce 3-fucosyllactos through improved enzymatic activity.

Modifying α1,3-fucosyltransferase and α1,2-fucosyltransferase enzymes boosts catalytic activity. This increases yields while reducing production costs. Traditional methods often struggle with low efficiency, high resource consumption, and longer production times. In contrast, Kyowa Hakko’s enhanced enzymes maximize raw material utilization, shorten production cycles, and improve scalability—helping manufacturers meet rising demand while ensuring a cost-effective and sustainable production process.

Nestlé: Multi-HMO Blends to Support Infant Gut Health

Nestlé has patented an HMO composition to promote a healthier gut microbiota and reduce harmful metabolites.

This formula combines 2’-FL, difucosyllactose (DFL), and lacto-N-neotetraose (LNnT) to shift gut fermentation toward beneficial saccharolytic processes. Nestlé’s innovation helps address metabolic imbalances and supports optimal gut health by reducing harmful metabolites like branched short-chain fatty acids. This breakthrough provides a framework for next-generation infant formulas prioritizing comprehensive digestive and metabolic well-being.

Genechem: Yeast-Based 3-FL Production for Scalable HMO Manufacturing

Genechem has patented an efficient method to produce 3-fucosyllactose (3-FL), a vital HMO for infant gut health. This process uses genetically modified yeast (Saccharomyces cerevisiae), a food-safe microorganism.

Incorporating the α-1,3-fucosyltransferase gene from Parabacteroides johnsonii alongside GDP-D-mannose-dehydratase and other enzymes enhances 3-FL production efficiency. Unlike conventional methods that rely on expensive, complex fermentation with pathogenic bacteria, this yeast-based approach lowers costs, ensures scalability, and maintains high-quality output. The result: a cost-effective, high-yield solution that makes 3-FL more accessible for premium infant formulas while supporting large-scale production needs.

Advancing HMO production comes with challenges—high costs, scalability issues, and evolving technologies. Tracking new developments across patents and research papers takes time.

Find other latest advancements in HMO production on Slate Pro.

Fill out the form below to request a demo:

The Future of Infant Nutrition

Both sialylated and fucosylated HMOs play distinct roles in infant nutrition. Sialylated HMOs are recognized for their benefits in cognitive and immune development, while advancements in fucosylated HMO production focus on overcoming challenges like high costs and scalability. Rather than shifting from one to the other, the industry is exploring optimized compositions that combine both to bring infant formula closer to breast milk.

Our Upcoming Infant Nutrition Innovation Trend Report further explores advancements in Sialylated HMOs and Fucosylated HMOs and other key trends in infant nutrition, including plant-based formulas, personalized nutrition, and more.

Sign up for the first copy of the report to explore the latest advancements in Infant Nutrition, the competitive landscape, and its impact on the industry.

Get access to our upcoming report

Fill the form to sign up

Also read: Infant Nutrition Startups breaking the one-size-fits-all model!

Authored By – Kulwinder Kaur and Ridhima Mahajan, Market Research