Only ~50% of the sorted PET is recycled back into food-grade materials. This is due to the high initial investment costs and infrastructure barriers to PET recycling.

Mechanical recycling accounts for the majority of PET recycling, but it is often limited to clean, sorted materials, producing lower-grade rPET. In contrast, chemical recycling, which can handle a wider variety of PET waste and preserve material quality, is gaining momentum.

Chemical recycling of PET is growing at ~8-10% annually, and it is estimated that by 2027, approximately. 0.5M tonnes of PET would be recycled via chemical routes.

Current estimates suggest that mechanical recycling processes account for approximately 90% of recycled PET, while chemical recycling accounts for only 10%. For instance, in Europe, of the 3.5 million tons of PET collected for recycling, approx 2.5 million tons are recycled via mechanical pathways & chemical recycling accounts for 0.26 million tonnes. In comparison, ~0.70 million tons of collected PET are lost during recycling processes.

Why are chemical recycling processes underutilized?

Chemical recycling processes can be broadly classified across three categories, each of which comes with its own set of challenges:

Pyrolysis & Gasification

What it is: Plastic is heated (with or without catalysts) to break it down into monomers or a mixture of hydrocarbons (fuels or building blocks).

Current Challenges: High energy consumption and a large carbon footprint. Further, the end product is pyrolysis oil, which is used as a fuel. Presently, the pyrolysis products are not suitable for producing rPET.

Solvolysis (Methanolysis, Glycolysis)

What it is: Uses chemical reactions (often with solvents or enzymes) to reverse polymer bonds, especially for condensation polymers like PET and polyamides – yielding monomers close to virgin quality.

Current Challenges: The process is cost-intensive and uses toxic solvents like ammonia and acetone.

Hydrothermal or Supercritical Water Processes (e.g., Hydrolysis, HydroPRS)

What it is: Uses supercritical water to break down mixed plastics into short-chain hydrocarbons for new plastics.

Current Challenges: The process requires robust equipment and is not effective for recycling LDPE, HDPE & PP.

The following five emerging technologies are addressing these challenges and helping create a more sustainable PET recycling ecosystem.

Promising PET recycling technologies at a glance

| Technology | TRL | Yield/Conversion | Feedstock Scope | Energy/Environmental Impact | Cost/Scale Estimates | Key Challenges |

| Supercritical CO₂ (BASF) | 7‑8 | 95%+ monomer yield | Primarily clear PET, food‑grade material | Low energy consumption, reduced CO₂ emissions | CAPEX: High; OPEX: Medium (Scaling costs high) | Scaling to an industrial scale; infrastructure investment |

| Induction Heating (Bobine) | 6‑7 | 45% increase in conversion efficiency | PET bottles (clean, sorted) | 55% reduction in CO₂ emissions | CAPEX: Medium; OPEX: Medium | Feedstock contamination, scaling from pilot to industrial |

| Glycolysis (Garbo) | 6‑7 | 100% yield (BHET) | Mixed PET (less contaminated) | Lower temperatures, reduced energy consumption | CAPEX: Medium; OPEX: Low | Feedstock quality, process optimization for large-scale |

| Air‑Moisture Recycling (Northwestern) | 4‑5 | 94% monomer recovery in 4 hours | Mixed/contaminated PET | Low energy, no toxic chemicals | CAPEX: Low; OPEX: Low | Scale for large volumes, optimization for diverse feedstock |

| Electrochemical Recycling (CU Boulder) | 4‑5 | High-quality monomers (ethylene glycol, terephthalic acid) | Clear PET, polyester waste | Ambient temperatures, no toxic solvents | CAPEX: Medium; OPEX: Low to medium | Feedstock separation, electrochemical cell optimization |

Solving the High Energy Consumption

BASF’s supercritical CO₂ reduces energy consumption and reliance on toxic solvents

While supercritical CO₂ requires high pressure, it operates at much lower temperatures (30–80°C) compared to conventional chemical recycling, which requires energy-intensive high temperatures. The process is also non-toxic and does not require flammable solvents, reducing both energy use and environmental impact.

BASF has significantly advanced the use of supercritical CO₂ in PET recycling by applying it to the depolymerization process – something previously limited to the decontamination phase by players like Nextech. In this process, supercritical CO₂ serves as both a solvent and a swelling agent, facilitating the breakdown of PET into reusable oligomers during rapid depressurization.

The European Union (EU) has taken a keen interest in this technology, funding projects like R-PETFOAM, which has received €2.5 million in backing to scale up supercritical CO₂-assisted PET recycling. This institutional support highlights the growing role of supercritical CO₂ in advancing a circular economy for plastics and achieving sustainability goals.

Similarly, they have also allocated €2.5 million in funding under the Just Transition Fund (JTF) to the Groningen startup Cescoc2 for scaling up supercritical CO₂-based PVC upcycling — highlighting significant institutional support.

(Sources – WO2025072953A1, WO2025072954A1, Research, UNIQUE, R-PETFOAM, Cescco2, Nextek)

Bobine’s chemical recycling increases conversion efficiency and reduces CO₂ emissions.

Bobine’s electromagnetic induction heating method addresses the challenge of high energy consumption in chemical recycling by efficiently heating PET. The process operates at lower temperatures than traditional pyrolysis, reducing CO₂ emissions by 55% and improving energy efficiency and the carbon footprint.

This technology can be deployed in existing pyrolysis plants, where the pyrolysis oils can be refined and converted to food-grade rPET. This method is also highly scalable, making it a promising solution for large-scale industrial use.

Bobine, a subsidiary of Saint-Gobain, specializes in electromagnetic induction for PET recycling. The process involves vaporizing the plastic, which is then cracked over a heated carbon bed to form PET oligomers. Inert gases like nitrogen (N₂) and argon are used to transport the vaporized plastic, preventing unwanted side reactions.

Bobine’s collaboration with Michelin has been instrumental in advancing this technology. The company has demonstrated significant improvements in conversion rates, energy efficiency, and cost-effectiveness, achieving a 45% increase in conversion rate compared to traditional pyrolysis methods. Bobine, along with Michelin, is set to establish a pre-industrial demonstrator of 1 ton/day by 2025 and expand it to 30 tons/day by 2028. Bobine’s process has the potential to produce high-quality, food-grade recycled plastics, making it suitable for high-grade food packaging.

(Sources – SICAT, WO2024042200A1, Bobine, Commercialization Scale, Integratability, EU Regulation, Pre-Industrial Demonstrator)

Finding these inventions is often tedious. But using research-scouting tools like Slate saves you plenty of time and effort. Slate is like ChatGPT, but for patents and research papers.

Try asking it about PET recycling and see how it finds objective, highly relevant results without fluff.

What are the latest innovations in PET recycling?

Addressing Feedstock Contamination and Process Yield

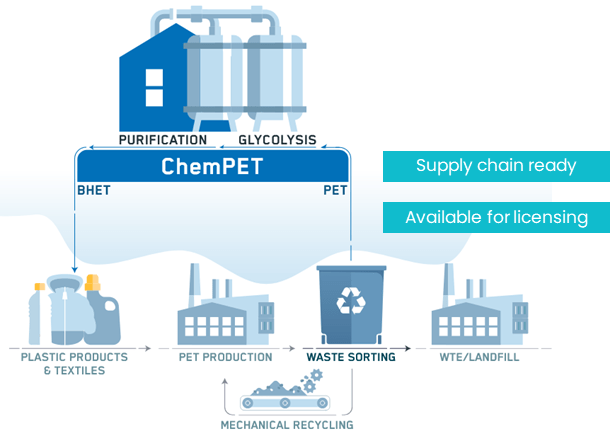

Garbo’s PET depolymerization improves reaction efficiency, producing 100% BHET yield

Glycolysis is one of the earliest-developed chemical recycling processes, in which PET is broken down into its monomers by reacting with ethylene glycol (EG). Conventional glycolysis processes are inefficient, requiring high temperatures and pressures that lead to substantial energy costs. Furthermore, they rely on homogeneous catalysts that are difficult to separate, creating purification challenges and waste streams.

Grabo’s patented technology overcomes these hurdles by enabling the complete conversion of PET into its monomer, BHET, with ~100% yield under much milder operating conditions.

The core of this innovation is the application of a novel sulfated niobia-based catalyst. The use of this high-activity catalyst enables the reaction to proceed efficiently at a much lower temperature (around 195°C) and at normal pressure, significantly reducing the energy footprint.

A key advantage lies in the catalyst’s solid, or heterogeneous, nature. Unlike liquid homogeneous catalysts that dissolve into the reaction mixture, this solid catalyst can be easily recovered after the reaction by simple filtration, minimizing extra steps & waste generation. Under these optimized conditions, the process achieves a 100% yield of PET to BHET in 220 minutes. Ultimately, this catalytic approach makes the chemical recycling of PET more economically viable and environmentally sustainable.

Garbo’s ChemPET project, funded by the EU with a €1.79 million grant, processes 6 tonnes of PET per day. Garbo has also partnered with players like Saipem and Plastipak to industrialize and globally commercialize ChemPET.

(Sources – WO2021214642A1, Commercialization Details, Garbo, Saipem, Plastipak, European Union)

Northwestern University’s air-moisture recycling handles contaminated feedstock without toxic chemicals.

Northwestern University’s air-moisture-based recycling method eliminates the need for toxic chemicals and energy-intensive sorting processes. It uses ambient air moisture to break down PET, making it ideal for mixed and contaminated PET waste.

This air-moisture-based method also reduces energy consumption and produces fewer byproducts. Using a non-toxic molybdenum catalyst and activated carbon, the process breaks the chemical bonds in PET. The moisture in the air triggers a chemical reaction that converts the PET into reusable monomers.

This method is highly sustainable and efficient, achieving a 94% monomer recovery rate within just four hours. The process also has scalability as its key feature, and it can work on a wide range of PET waste, including colored plastics and textiles.

Innovations Overcoming Harsh Chemical Usage

CU Boulder’s electrochemical PET recycling avoids high temperatures and toxic chemicals.

CU Boulder’s electrochemical recycling method eliminates the need for high temperatures and toxic solvents. The technique uses electricity to break apart PET and introduces oxygen to accelerate its decomposition. This approach operates at ambient temperatures, making it energy-efficient and more straightforward than traditional high-temperature chemical recycling methods. This reduces both energy consumption and the environmental impact of the recycling process.

This method involves an electrochemical cell where a current is passed through a mixture of PET and a polar aprotic solvent (such as acetonitrile). As the current flows through the system, it generates superoxide (O2*) by reducing dissolved oxygen, which then breaks down the PET into products such as ethylene glycol and terephthalic acid.

One notable aspect of this method is the ability to use a solvent and electrolyte to enhance the reaction, which could potentially be optimized for various types of polyesters beyond just PET. This process offers an eco-friendly alternative to traditional plastic recycling methods, eliminating the need for high temperatures or toxic chemicals. Additionally, it enables the recovery of valuable monomers for reuse in high-quality applications, making it a promising solution for improving the circularity of PET recycling.

(Sources – Patent)

Conclusion

The global PET waste crisis demands innovative recycling solutions to tackle the flaws of traditional methods. These include high energy use, sensitivity to contamination, and material degradation. Fortunately, new chemical recycling technologies are stepping up.

BASF’s supercritical CO₂ depolymerization, Bobine’s induction heating, and Garbo’s nitrogen-assisted glycolysis are improving energy efficiency and conversion rates while better managing contamination. Meanwhile, Northwestern’s air-moisture catalysis and CU Boulder’s electrochemical recycling offer eco-friendly methods without harsh chemicals or high temperatures.

Despite their promise, challenges remain. R&D leaders need to focus on scaling, managing costs, and addressing regulatory hurdles. With ongoing research, investment, and collaboration, we can enhance PET recycling, reduce environmental impact, and move toward a circular economy for plastics.

If you have any additional queries regarding the above PET recycling innovations, please reach out to our industry experts via the form below.

Let's get in touch!

Please share all your queries with us below