As sustainability pressures grow, dairy brands are shifting to recyclable, lightweight, and biodegradable materials like rPET and paper-based wraps. However, these advancements introduce new challenges in product freshness, barrier protection, and supply chain feasibility. This leads to shorter shelf life, higher waste, and increased manufacturer costs. The current trends in dairy packaging aim to solve this.

Companies like Coca-Cola, Sidel, and Wihuri Packaging are advancing their innovations in PET bottles, paper-based wraps, and plastic-free alternatives to create better packaging for the dairy industry.

This article explores key innovation trends in dairy packaging based on patent filings and ongoing research. It offers insights into the latest developments made by dairy and packaging companies like Coca-Cola, AMCO, and DMK, and their market impact.

Many such innovations by industry giants are shaping industries like dairy and alcohol. This report covers key challenges, emerging technologies, and industry shifts. Gain industry insights to tackle your packaging challenges. Fill out the form below to get the latest packaging trend report.

Let’s begin with the first trend:

1. Recyclable PET With Light Protection Will Preserve Dairy Products

Dairy companies use recyclable PET and rPET bottles, paper-based cartons, and bio-based films to reduce plastic use. They also offer refillable glass bottles and lightweight packaging to reduce packaging materials. While these solutions help sustainability, they also come with challenges.

For instance, Bio-based materials struggle to block moisture, grease, and oxygen, which shortens shelf life. Recyclable PET bottles with light-blocking additives are hard to process. Multi-layer cartons with plastic and aluminum are tricky to recycle. Sustainable packaging also costs more, making it harder for brands to switch.

Source: Webpackaging

To solve these issues, companies like Sidel and Wihuiri are developing better coatings, cost-effective rPET solutions, and improved recycling. They are also exploring fully recyclable PET bottles with barrier protection and scalable paper-based packaging that keeps dairy fresh. These efforts aim to create packaging that is both sustainable and practical for dairy brands and consumers.

1. Coca-Cola’s Recyclable PET Bottles Block 99% Of Light To Prevent Milk Spoilage

Coca-Cola has developed a multi-layer PET bottle designed for light-sensitive dairy products like milk. It blocks over 99% of light in the 400-700 nm range, preventing spoilage. Instead of using aluminum or inorganic pigments, the bottle features an opacifying additive that keeps it fully recyclable within PET waste streams. This eliminates a major recycling challenge while preserving product freshness.

The innovation aligns with Coca-Cola’s broader dairy strategy, especially after it fully acquired Fairlife in 2020—a high-protein milk brand that has grown rapidly in the U.S. The advanced packaging supports Fairlife’s premium positioning by extending shelf life without compromising recyclability.

2. Sidel’s Lightweight PET/rPET Bottles Are Replacing Hard-To-Recycle Polyethylene

Sidel’s latest innovation is a lightweight PET/rPET bottle designed for Liquid Dairy Products (LDPs). Using low-pressure blow molding technology, the bottle reduces energy consumption during production while remaining highly durable. Its optimized neck-to-body ratio minimizes material use, making it 5g lighter for a 150mL bottle. The design ensures full recyclability within PET systems, helping brands transition away from hard-to-recycle high-density polyethylene (HDPE) and polystyrene.

Source: Sidel

3. Wihuri Packaging’s Paper-Based Wraps Are Leak-Proof

Wihuri Packaging has introduced a paper-based wrap as an alternative to plastic and aluminum laminates used in butter and greasy dairy products. The wrap’s central paper layer offers excellent dead-fold properties, ensuring secure wrapping without adhesives. It also features a natural water-based coating for high grease resistance without synthetic polymers. This solution helps brands meet growing market demands for plastic-free, recyclable packaging while maintaining essential barrier properties.

Recommended Packaging Read

2. Active and Antimicrobial Packagings Are Replacing Chemical Preservatives

Traditional dairy preservation relies on chemical additives and refrigeration, but these methods alter taste, texture, and increase costs. Spoilage remains a major issue even with cold storage, leading to waste and financial losses.

Packaging companies like Purac and AMCO are investing in active and antimicrobial packaging to solve these challenges in the dairy industry. These innovations are especially valuable for highly perishable dairy products and plant-based alternatives like vegan cheese.

1. Purac Biochem’s Antimicrobial Polymer Sheets Are Without Chemical Preservatives

Purac Biochem has developed an antimicrobial polymer sheet to replace traditional chemical preservatives in dairy packaging. This vinyl polymer surface layer is infused with C8-C16 acyl lactylates, inhibiting bacterial growth. The antimicrobial effect remains stable throughout packaging, ensuring food safety and extended shelf life. This innovation helps maintain dairy freshness while meeting consumer demand for fewer additives. It is an effective alternative to traditional chemical preservatives.

2. AMCO Technology’s Breathable Cheese Packaging Keeps Excessive Moisture Away

AMCO Technology has introduced breathable cheese packaging to solve the excessive moisture buildup issues in traditional packaging. The packaging uses microporous and non-microporous films to regulate airflow, allowing natural cheese ripening while preventing spoilage. The film layers, made from polyethylene, polypropylene, and nylon, ensure optimal oxygen and moisture permeability. This technology preserves cheese texture, flavor, and quality over time. It is ideal for both traditional and plant-based cheeses.

3. DMK’s Aseptic Hot Packaging for Vegan Cheese Improves Shelf Life

DMK Deutsches Milchkontor has developed an aseptic hot packaging method for vegan cheese, reducing bacterial contamination during processing. This method sterilizes the packaging and fills it with liquid vegan cheese before sealing it in a multi-layer laminate bag made of linear low-density Polyethylene (LLDPE). The result is minimal bacterial presence, improved shelf stability, and longer freshness. This innovation ensures keeping the cheese in a liquid form for easier and better processing and later use.

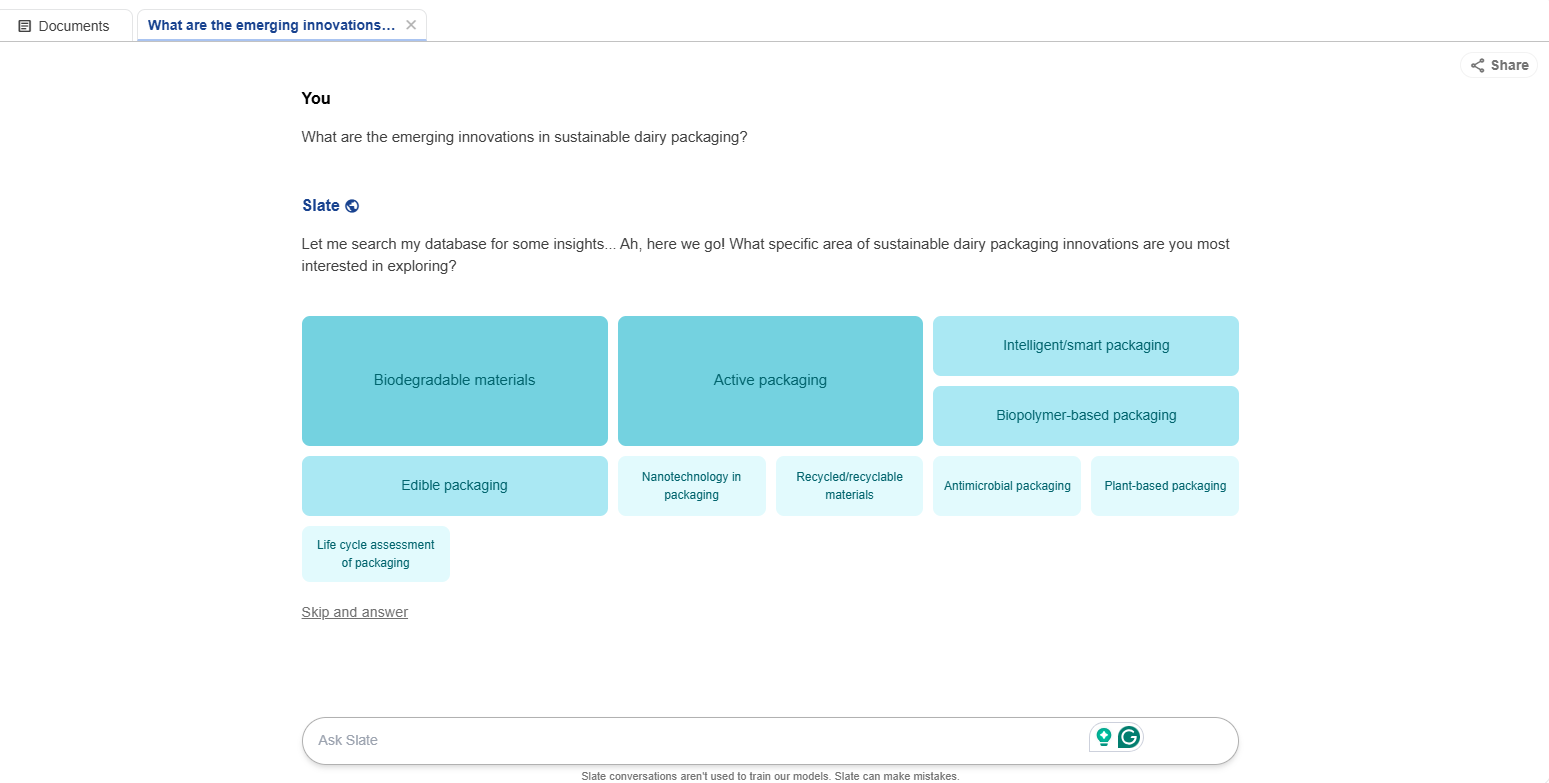

Navigating these industry shifts requires access to new material innovations before they enter the market. However, with loads of ongoing research, it is nearly impossible for R&D heads to keep track of these innovations. This is where Slate by GreyB comes in. Just ask the AI assistant, “What are the emerging innovations in sustainable dairy packaging?”; it’ll give you the latest innovations to track, compare, and adopt.

Source: Slate Dashboard

3. Barrier technologies are becoming more advanced and sustainable

In dairy packaging, plastic-based barriers provide high stability and protection but make recycling challenging. Conversely, while paper-based alternatives are easy to recycle, they lack durability or sufficient protection. Additionally, chemicals leaking from packaging and barriers alter the taste and aroma of products. Sustainability and cost are also factors to consider when selecting barrier materials for highly sensitive dairy products.

The industry is adopting advanced barrier technologies that improve shelf life, product integrity, and sustainability without sacrificing recyclability or safety to solve these issues.

1. Nestlé’s Multi-Layer PHA Containers Don’t Let Chemicals Leak Into the Food

Nestlé has created a multi-layer PHA container to address chemical contamination and sustainability issues. It has a PHA base layer for biodegradability, a polymer layer for strength, and a thin metalloid or carbon barrier to block harmful emissions. This design prevents the release of crotonic acid, which can affect taste and smell. With this packaging innovation, Nestlé can ensure that the organoleptic properties of dairy and beverage products stay intact while sturdy biodegradable packaging protects them.

2. Delsci & Delfort Group’s Paper-Based Barrier Packaging Blocks Oxygen and Water

Delsci and Delfort Group collaborated to develop paper-based barrier packaging that improves food preservation. The packaging has a multi-layer structure, in which the base paper layer is integrated with two more layers. One of these is oxygen-blocking, and the other is for water-resistance. These coatings delay spoilage and increase the shelf life of dairy products. The packaging also has cross-linked hydroxy group polymers and waxes, which are implied for a smooth texture and increased durability. This innovation offers an eco-friendly alternative to traditional plastic films, providing excellent barrier properties while maintaining sustainability.

3. Anhui Zijin’s Composite Film for Milk Powder Protects Against Moisture And Light

Anhui Zijin has focused on improving milk powder packaging, where exposure to light and moisture can lead to oxidation and caking. The innovative multi-layer composite film incorporates sodium montmorillonite nanosheets and a modified ethylene-vinyl alcohol EVOH barrier. It offers exceptional protection against environmental factors like light and moisture. With water vapor permeability as low as 0.04 g/(m²·24h), this film prevents oxidation and caking of milk powder. It ensures that milk powder remains fresh, stable, and free from clumping over long storage periods.

Recommended Packaging Read

4. Making the dairy industry zero-waste with edible and functional packaging

Traditional dairy packaging, such as plastic films, parchment paper, and aluminum foil, often contributes to waste and environmental pollution. While some biodegradable options exist, many require industrial composting or specialized disposal methods.

The push for zero-waste solutions drives the dairy industry to explore edible and functional packaging. With these innovations, companies aim for more eco-friendly and convenient consumer packaging.

1. Amai LLC’s Biodegradable Butter Packaging Film Will Replace Parchment and Aluminium Foil

Amai LLC has developed an eco-friendly, edible, and compostable butter packaging film that replaces traditional parchment and aluminum foil. This film combines a composite paper layer with a biodegradable polylactic acid (PLA) and polyhydroxy butyrate layer. It preserves butter’s aroma, texture, and moisture. The packaging is fully degradable in composting conditions, making it a zero-waste packaging solution for the dairy industry.

2. Amco Technology’s Degradable Butter Packaging Meets Strict Regulatory Compliance

Amco Technology has introduced a biodegradable butter packaging film that meets strict environmental regulations. Made from PLA and other compostable materials, this packaging provides flexibility, durability, and antioxidant properties. It also has stable barrier performance under storage conditions for maintaining the quality and freshness of dairy products.

3. Walterwerk Kiel’s Moisture-Resistant Coating is Edible

The water repellent or hydrophobic glaze for sweet waffle cups developed by Walterwerk Kiel is a moisture-resistant edible packaging solution. While designed for confectionery, this innovation highlights how moisture-resistant edible coatings can be applied to butter and dairy products to prevent oxidation and contamination. This technology could inspire the development of functional and moisture-resistant coatings that enhance dairy packaging durability while remaining fully biodegradable or edible.

Future Outlook

Changing sustainability rules like PPWR and EPR, and consumer demands are forcing the dairy industry to rethink its packaging strategies. Increased packaging material and market costs are also factors behind the constant change in dairy packaging. Despite these changes, sustainability, recyclability, functionality, and cost-efficiency remain key pain points for the dairy packaging industry.

Recent innovations in PET bottles, paper wraps, antimicrobial packaging, and barriers are solving some of these pain points. They help keep products fresh, prevent spoilage, and extend shelf life while reducing environmental harm. Companies are now more focused on innovations that can provide balanced solutions to dairy packaging challenges.

The dairy industry is changing fast. Stay informed to make smarter R&D and business decisions. Our Dairy Industry Trend Report helps you:

- Track consumer trends to create products people want

- Find market gaps and new opportunities

- Discover cost-saving innovations

- Stay ahead of competitors

- Improve branding and marketing for better consumer engagement

Download the report now to get key insights and stay competitive!

Dairy Industry Trend Report 2025

Download the ReportRead Dairy Industry Related Posts: