The leather industry faces a recycling crisis, with millions of tons of waste in landfills due to complex material compositions.

In 2022, Singapore alone generated 254,000 tons of textile and leather waste, of which only 2% was recycled. The challenge is not removing waste but finding ways to recycle leather sustainably without losing its quality.

This article explores the key challenges and emerging solutions shaping the future of leather recycling worldwide.

This Non-Bio Leather Is the Answer to Sustainable Leather Supply Hurdles

The synthetic leather industry has long faced challenges with recycling due to the use of mixed materials in over 70% of products. These materials make recycling difficult and lead to more waste in landfills. However, San Fang addresses this problem with its all-TPU (Thermoplastic Polyurethane) leather, which utilizes a single material for all layers, making it easier to recycle.

This innovation streamlines production by minimizing waste, enabling manufacturers to scale up production more efficiently. Unlike bio-leathers, which rely on plant-based materials such as cacti or grapes, TPU leather does not depend on agriculture, offering a more reliable and consistent supply of material. This makes it an excellent choice for industries such as automotive, footwear, and fashion, where durability is crucial.

With its high resistance to wear and tear, TPU leather outperforms both plant-based and biodegradable leathers, lasting longer and reducing the need for replacements. Additionally, San Fang’s TPU leather is free from harmful chemicals, aligning with global sustainability efforts. Regulations worldwide, such as the EU’s REACH and California’s Proposition 65, are promoting safer and more sustainable products. San Fang is already ahead of the curve, offering a solution that meets these growing demands.

Breakthroughs in synthetic leather recycling are transforming sustainability efforts, from closed-loop materials to scalable circular solutions. Companies that track these innovations will gain a competitive edge, reduce waste, and meet evolving regulations.

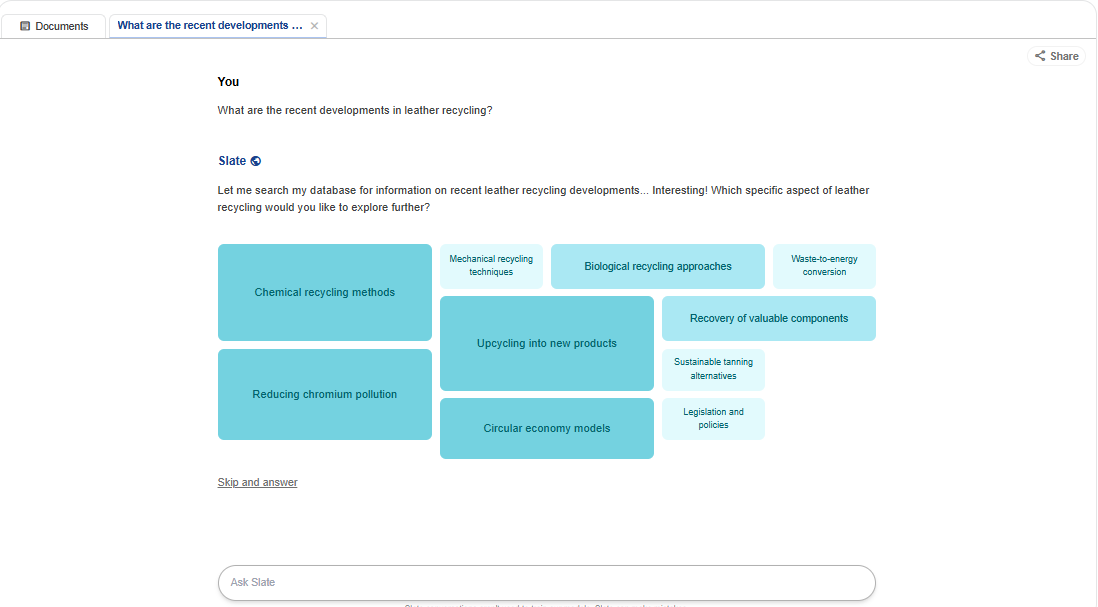

With SLATE, you can instantly find the technology, patents, and research shaping the future of sustainable synthetic leather materials. No need to sift through endless reports, just ask SLATE, GreyB’s AI-powered tool delivers insights in minutes.

Fiber-Processing Technique turns Cowhide Waste into Durable Leather for Automotive and Fashion

Traditional leather recycling methods often result in a 30-40% reduction in tensile strength and abrasion resistance due to the breakdown of fibers during processing. This compromises the material’s performance, limiting its use in high-demand sectors like automotive, aerospace, and luxury fashion. Furthermore, the use of multi-material composites in conventional recycling further weakens the leather, making it unsuitable for demanding applications.

To overcome this challenge, an innovative fiber-processing technique has been developed that transforms leather waste into high-quality fibers. This process involves spinning the fibers into threads, weaving them into fabric, and reinforcing the fabric with short cowhide fibers, which significantly improves both tear resistance and tensile strength. The result is a durable, smooth, and resilient material that meets the rigorous demands of industries like automotive interiors and luxury fashion, where durability and texture are paramount.

By reusing both cowhide waste and leather fibers, the process minimizes material loss, resulting in improved production efficiency compared to traditional leather recycling methods, which typically struggle with higher waste rates.

A Dry Airlaid Process Cuts Down Thousands of Liters of Water

The leather industry faces significant challenges due to its traditional production methods, which are resource-intensive and environmentally harmful. For instance, producing just one kilogram of leather can require 6,000 to 17,000 liters of water, along with large amounts of chemicals, resulting in substantial waste and pollution.

Atko Planning Inc. addresses this issue with a dry manufacturing method that eliminates the use of water and harmful chemicals. Using a dry airlaid technique, it produces stronger, more durable leather with consistent texture, reducing environmental impact and minimizing energy use and waste.

The method also enables blending leather fibers with other materials, thereby enhancing versatility for industries such as fashion, automotive, and furniture. By improving durability and reducing waste, it meets the performance needs of high-stress applications, such as automotive interiors, while supporting sustainability goals.

Atko’s innovation aligns with the global push for sustainable manufacturing, helping industries meet stricter regulations, such as the EU’s Circular Economy Action Plan, which focuses on waste reduction and material recycling.

A Silk Bonding that Turns Leather Waste Into Durable, Vibrant Luxury Fabrics

Many luxury brands, such as Gucci, Louis Vuitton, and Hermès, are increasingly adopting sustainable alternatives to reduce their reliance on virgin leather while maintaining their high-end aesthetics. Evolved By Nature Inc., a chemical company, offers a breakthrough with its silk protein bonding technology, transforming leather waste into luxury fabrics with superior dye retention, softness, and durability. By utilizing silk fibroin, a natural protein, this process strengthens leather fibers by enhancing their cohesion at the molecular level. Unlike traditional bonded leather, which often relies on synthetic adhesives that create weak fiber bonds, silk fibroin integrates with the leather’s fibers, improving texture, performance, and overall durability.

The method reduces material waste by efficiently repurposing leather offcuts and discarded leather fibers, which would typically be discarded in traditional processes. Silk fibroin bonding ensures these fibers are integrated into the final product, minimizing waste and maximizing the use of available leather material. Unlike traditional methods that rely on synthetic additives, silk protein bonding uses natural silk fibroin, ensuring a cleaner and more sustainable process. It also aligns with global environmental standards, including ISO 14001, focused on reducing environmental impact, and the Global Recycled Standard (GRS), which verifies the use of recycled materials.

With enhanced strength, color vibrancy, and softness, silk protein-bonded leather is ideal for luxury fashion and premium upholstery, providing a sustainable alternative to traditional leather without compromising on performance or aesthetics.

Recommended Read

What Innovations are your competitors secretly working on? Ask Slate.

Chromium pollution has been a persistent environmental issue in the leather processing industry, primarily due to the use of chromium salts in the tanning process. As the leather industry faces increasing pressure to adopt more sustainable practices, companies are actively working on innovative methods to reduce or eliminate chromium from their operations. With SLATE, you can instantly discover technologies, research studies, and patents your competitors are filing in chromium extraction and circular economy solutions—all in minutes.

Instead of spending hours searching through scattered reports and publications, just ask SLATE, and get data-driven insights on:

- Companies leading chromium extraction innovations

- Latest research and patents in sustainable leather waste management

- Emerging technologies in circular leather production

Authored By – Bhaskar Tiwari, Patent Analytics