Cutting down sugar in baked goods isn’t just about lowering sweetness. Manufacturers have to rethink structure, moisture, browning, shelf life, and flavor—all of which sugar naturally delivers. Replacing these functions means adding more ingredients to the label of the product. Suddenly, a clean-label muffin with five pantry-friendly ingredients turns into a complex formula with a dozen unfamiliar additives. These additives with INS numbers appear technical to everyday consumers, making the product unappealing.

From October 2025, a ban will be imposed on TV and online ads for foods high in fat, sugar, or salt (HFSS) in the UK. Such regulations are forcing bakery brands to reformulate using new ingredients and sugar alternatives to maintain their brand visibility.

Industry analysts have warned that this regulatory pressure will lead to resource shortages and added strain on supply chains across the UK and Europe.

This puts manufacturers in a tough spot: how can they meet the increasing demand for clean-label products while controlling costs and maintaining consumer appeal?

To effectively navigate this landscape, brands must look beyond traditional sweeteners and explore emerging technologies. This article explores four innovative solutions that can help bakery brands reduce sugar without the hassle of sourcing new ingredients and worrying about their potential health impacts.

SPC Korea is Generating Prebiotic FOS During Baking, Reducing Sugar Without Additives

Fructooligosaccharides (FOS) are being increasingly explored for sugar reduction in the F&B industry due to their naturally sweet taste and low calorie content. However, it is observed that directly adding FOS to the batter degrades the volume and texture of the final product.

SPC’s patented technology addresses this challenge by incorporating the invertase enzyme into the dough or batter during production. The enzyme generates FOS naturally during the baking or fermentation process. This way, manufacturers can increase the FOS content and reduce sugar without affecting the texture or physical properties of their bakery. FOS, being a well-known prebiotic, also enhances the nutritional value of the final product. This method eliminates the need for additives, enabling manufacturers to align with the growing consumer demand for clean-label items.

The innovative technique can produce a wide range of low-sugar bakery products, including bread, cookies, and jam. However, the right amount of invertase and baking time are essential for the best results. For example, for castella cake, it is recommended to add invertase at a concentration of 1.0 to 2.0 INU per gram of dough and let it react for 30 to 40 minutes. For sweet bread, invertase should be added at a concentration of 0.20 to 1.8 INU per gram.

Incredo’s Protein Embedded Sweeteners Stick to the Tongue for Lasting Sweetness

Food-tech companies are increasingly exploring proteins like brazzein, monellin, and thaumatin to replace sugar. A major drawback of these proteins is that they can cause a dry, puckering sensation in the mouth due to their tendency to interact with moisture. Proteins interfere with taste receptors, reducing the sweetness perception that consumers associate with sugar. Manufacturers have to use additives to compensate for the reduced sweetness, which in turn increases the ingredient list and production costs.

Incredo solved these problems with protein localization. In this process, proteins are embedded within sweetener particles (like sugar) to enhance sweetness perception. The proteins in the sweetener particles stick to the tongue and hold it in place, making the sweetness last longer. This is a cost-effective way of increasing sweetness perception that aligns with a clean-label approach.

Recommended Read

Coca-Cola Uses Gene-hacked Fruits to Produce Sweet Proteins

Existing methods for producing sweet proteins, like brazzein, use GMOs or chemical processes; both these methods have safety concerns when used in food-grade products. Additionally, these methods require specialized equipment and lengthy processing, making them costly and unsuitable for large-scale production.

Therefore, Coca-Cola developed a method for producing brazzein using genetically modified plants. The process involves inserting the genes responsible for producing brazzein into the DNA of a plant that does not naturally produce it, like watermelon. This genetic transformation uses techniques like genome editing or recombinant DNA technology. It enables the modified plant to produce brazzein in its fruits, seeds, and other parts.

The method allows for the mass production of brazzein in easy-to-grow plants. Compared to other methods, such as chemical synthesis or microbial fermentation, it provides a more cost-effective and sustainable way to produce natural sweeteners.

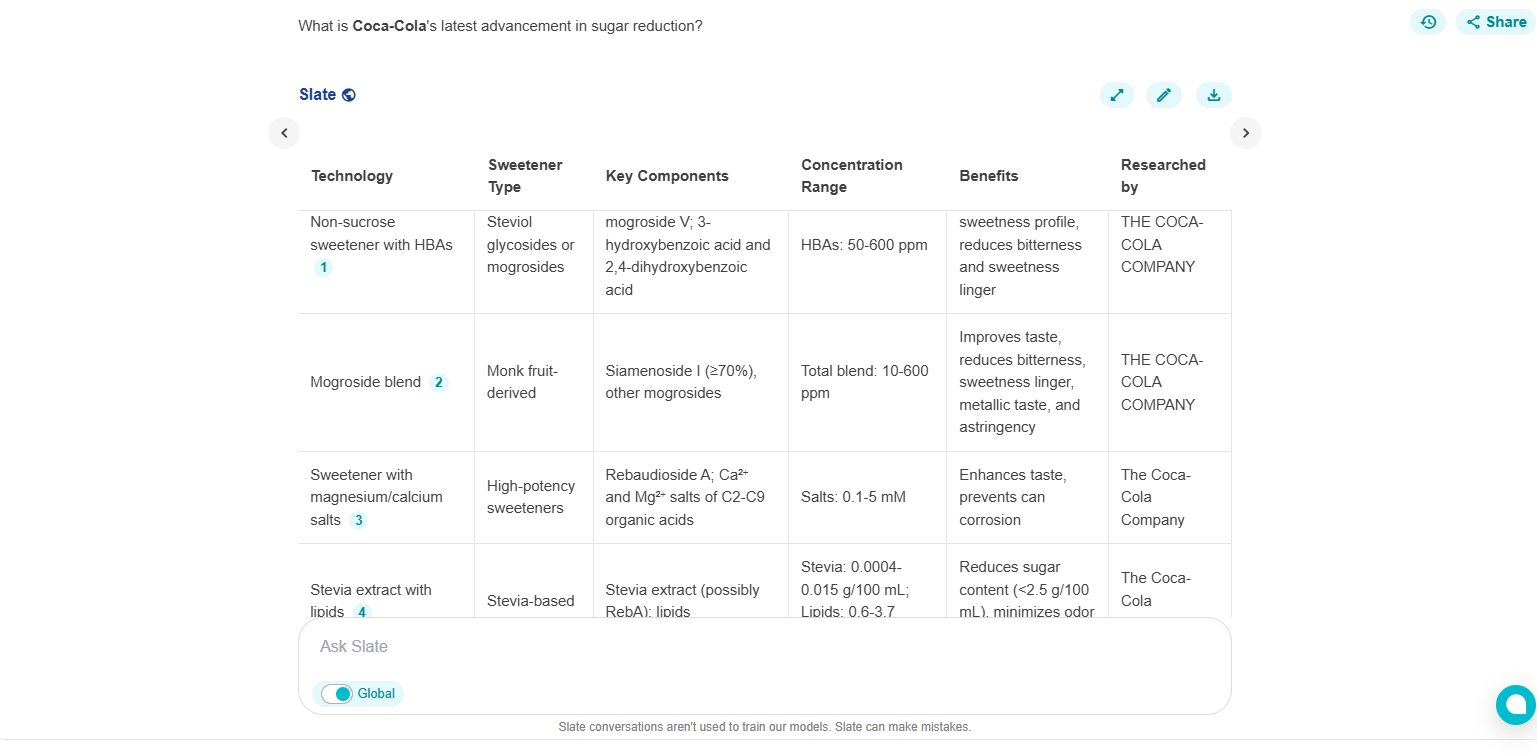

This innovative use of genetically modified plants is just one part of Coca-Cola’s broader strategy to reduce sugar content. The beverage giant is also exploring non-sucrose, steviol glycoside, and mogroside sweeteners. Keeping up with such R&D activities is key to maintaining the competitive edge. Stay one step ahead with proactive competitive research on our AI-based research tool, Slate.

MIT and Harvard’s Sugar-Blocking Enzymes Let You Eat Sugar Without Absorbing It

Researchers at MIT and Harvard have developed a method to address health issues associated with high sugar content by utilizing enzyme-polymer conjugated particles. The patent describes a composition that converts sugar into a form that is difficult for the body to digest, thereby reducing the amount of sugar absorbed. The composition consists of a particle that contains an enzyme to modify the sugar and an inhibitor that prevents the enzyme from activating prematurely. However, once the composition enters the gastrointestinal (GI) tract, environmental conditions, such as pH or ionic strength, trigger the inhibitor to release its hold on the enzyme. This activation enables the enzyme to convert sugar into a polymer that the body cannot absorb easily.

In some cases, polymers derived from sugar, such as fructooligosaccharides, act as prebiotics that promote gut health. This technology can be applied to a variety of foods, including juices, snacks, and bakery products, providing a healthier and more sustainable approach to reducing sugar in everyday diets.

Conclusion

Despite these advances, the journey to sugar reduction in bakery is filled with complexities. From ensuring the technical feasibility and scalability of new solutions to predicting market acceptance and consumer preference, there are many factors to consider.

If the HFSS regulations are threatening your product line, consider examining what your competitors are doing to strike a balance between sugar reduction, compliance, and consumer satisfaction.

Our sugar reduction report reveals proven solutions that top companies adopted to reduce sugar while cutting costs, improving flavor profiles, and meeting regulatory and market demands. Fill out the form below to get the full report.

Authored By – Tamanpreet Kaur, Market Research