Membrane-based lithium extraction has emerged as a promising alternative to traditional lithium extraction methods, offering cleaner and more efficient processes. Some advanced membrane technologies, like ElectraLith’s DLE-R, can extract lithium without water or chemicals.

This process significantly reduces the environmental footprint of lithium extraction. However, it also has some drawbacks. These include high cost, durability concerns, and low scalability due to slower processing.

Innovators like LiTHOS and LihyTech are solving this problem by tapping into renewable energies and recycling 98% of the water consumed.

This study explores these emerging membrane-based lithium extraction technologies, notable innovations in this field, and the real-world viability of such implementations.

Comparing Conventional vs. Membrane-Based DLE

| Benchmark | Conventional DLE | Membrane-Based DLE |

| Carbon Footprint | High due to energy-intensive processes. | Significantly lower due to reduced energy demands and renewable energy integration. |

| Water Footprint | High water consumption for washing and regeneration. | Needs minimal external water. Holds potential for brine recycling. |

| Renewable Energy Integration | Limited | High potential for integration with renewable energy sources |

| Operating Costs | Initial investment is generally lower | Higher initial investment due to membrane costs. Possibility of higher long-term costs due to membrane replacements |

| Separation Efficiency | Lower selectivity and efficiency | High selectivity (~99%) and efficiency (over 80%) |

Keep a track of the latest innovations and key players advancing in membrane based lithium extraction on SLATE.

Key Innovations in Membrane Technologies

Pure Lithium Converts Brine to Battery technology

Boston-based Pure Lithium has developed a membrane technology that can produce a lithium anode by directly extracting lithium metal from brine. This invention bypasses conventional lithium compound production as an intermediate and reduces the cost of lithium batteries by 80%. In 2024, the company received a patent grant for this technology.

The company also recently announced a joint agreement with Saint Gobain Ceramics. The collaboration aims to commercialize Pure Lithium’s membrane technology using Saint Gobain’s manufacturing expertise.

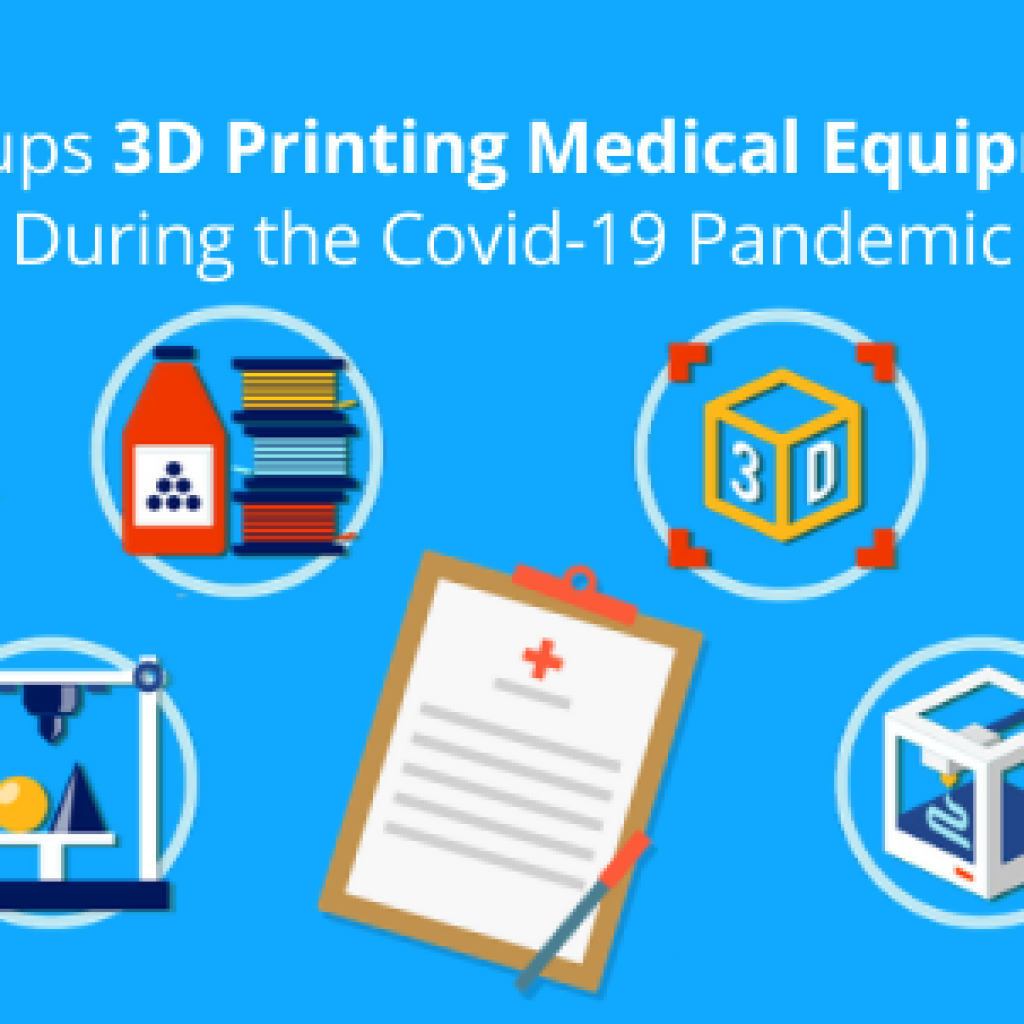

EnergyX Created a Sustainable Lithium Separation Technology

EnergyX has developed a Lithium-Ion Transport and Separation Technology (LiTAS™) that efficiently separates lithium ions even from highly saline brines. By integrating membrane separation units, this technology minimizes water usage and reduces lithium loss. It also eliminates harmful chemicals, making it a more sustainable production method.

The company has made significant strides toward commercializing its LiTAS™ technology. In 2022, the company deployed its first pilot plant at Bolivia’s Salar de Uyuni, the world’s largest lithium reserve. This pilot aims to validate the technology’s efficacy in real-world conditions.

LiTAS™ technology requires significantly less energy compared to traditional evaporation pond methods. Conventional methods can take up to 18 months to extract lithium, while LiTAS™ can achieve the same in just 1-2 days! This makes it significantly more cost-effective and commercially scalable.

Stanford’s New Membrane Technology Uses 90% Less Power Than Usual Methods!

Dr. Yi Cui’s team at Stanford University specializes in nanotechnology, materials science, and sustainable energy. They have developed a membrane technology that reduces production costs by 40% per ton. This translates to approximately $3,500 to $4,400 per ton of high-purity lithium hydroxide, compared to about $9,100 per ton for traditional methods.

This extraction process consumes only 10% of the electricity required by current methods, making it much more energy-efficient. It achieves 99% selectivity with an energy requirement of only 1.1 kWh/kgLi, a tenth of traditional DLE methods.

This system has demonstrated continuous lithium extraction capability for over 100 hours, with 100% selectivity. The low cost and high yield potential make this a promising lithium extraction solution that can be commercialized.

ElectraLith’s Renewable Energy-Powered Process Needs No Water

ElectraLith is a Melbourne-based startup backed by Rio Tinto mining company. This startup’s lithium extraction technology eliminates the need for water and chemicals.

It can operate entirely on renewable energy. This waterless DLE-R™ (Direct Lithium Extraction and Refining) technology produces battery-grade lithium hydroxide in a single step, ensuring high purity and quality of the final product. It can be scaled to various lithium sources, such as brines, geothermal, oil fields, recycled material, and spodumene deposits.

ElectraLith has secured approximately $17 million in Series A funding to develop its first pilot plant at Rio Tinto’s Rincon operation in Argentina, with plans for two additional pilot plants.

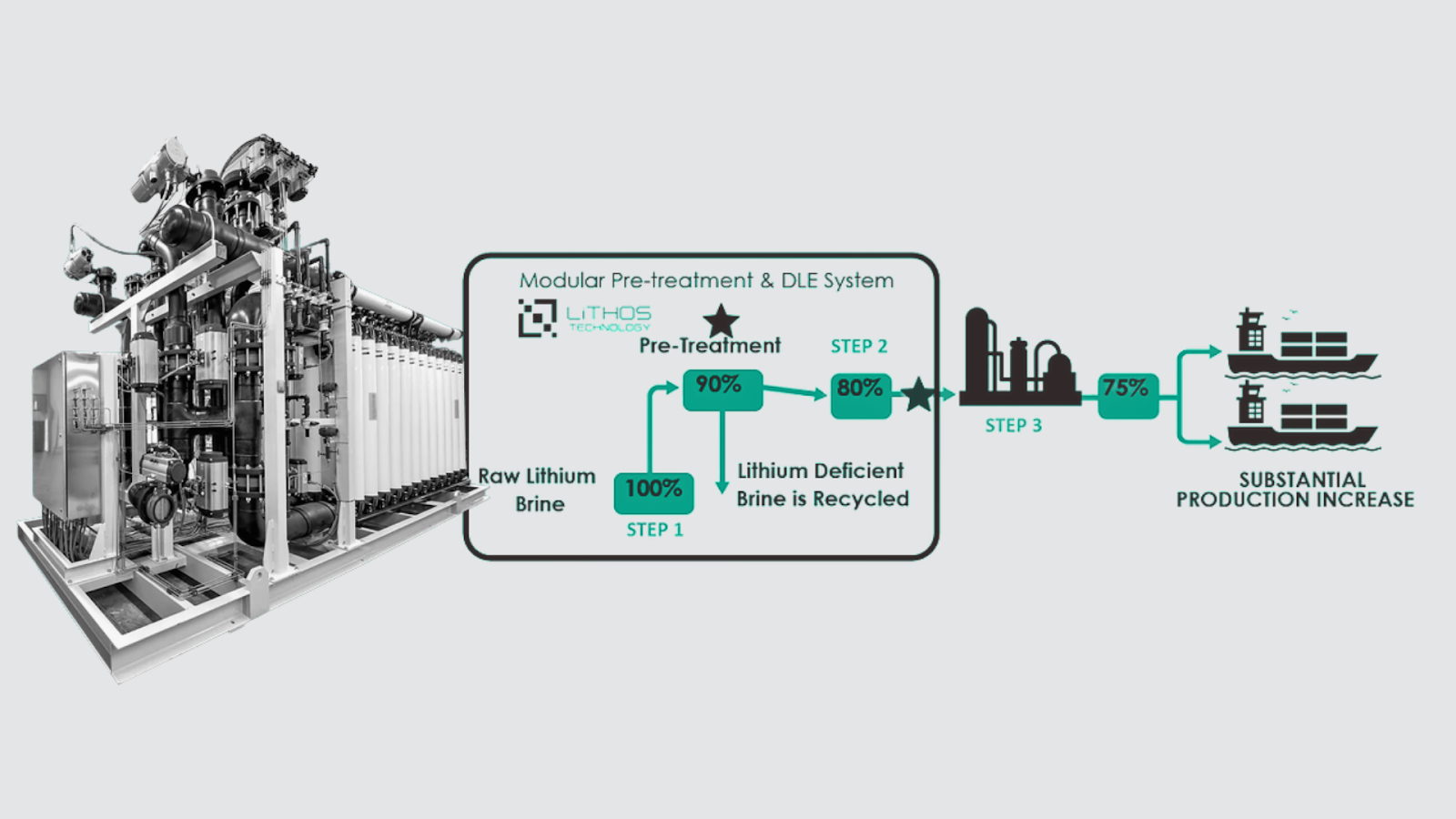

LiTHOS Group’s Hybrid Membranes Recycle 98% Water Used

LiTHOS’s AcQUA technology uses pressure to force brine through membranes to pre-treat it. This eliminates evaporation ponds and recycles 98% of input water. This innovation significantly reduces the environmental impact of brine processing.

SQM, a global mining company, conducted laboratory-scale tests on LiTHOS’s extraction technology using brines from the Salar de Atacama. The results showed that LiTHOS’s technology achieved high rejection rates of impurities such as magnesium, boric acid, calcium, and sulfates. This is essential for producing high-purity lithium.

Furthermore, the tests validated the hybrid membrane’s effectiveness in increasing lithium concentration without using freshwater or harmful chemicals.

LihyTech’s Ceramic Membranes are 100x Cheaper than Others.

In collaboration with Aramco, LihyTech has developed durable ceramic membranes for lithium extraction from low-concentration sources like seawater and oilfields. These membranes cost less than $10/m², compared to over $1,000/m² for other technologies, making it a cost-effective and scalable solution.

Their pilot plant at KAUST Research and Technology Park successfully processed oilfield-produced water, extracting battery-grade lithium. The technology has received investments from Ma’aden and KAUST Innovation Venture, highlighting its commercial potential.

Future Prospects and Challenges

For membrane-based DLE to replace conventional methods, several hurdles must be addressed:

- Cost Reduction: Lowering membrane manufacturing costs is critical for commercial scalability.

- Durability Enhancements: Developing membranes that withstand extreme operational conditions will reduce replacement frequency.

- Lifecycle Analysis: Addressing the environmental impact of membrane production and disposal is essential for true sustainability.

- Scalability: Demonstrating the feasibility of large-scale operations will be key to widespread adoption.

Conclusion

Membrane-based lithium extraction addresses critical challenges of high costs, scalability issues, and limited durability. As the global demand for lithium surges, these advancements will help meet industrial needs while reducing environmental impacts.

Collaboration among researchers, industries, and policymakers will be critical to overcoming current barriers and realizing the full potential of membrane technologies. According to market forecasts, global lithium demand is expected to grow 18% annually by 2030, driven by the increasing adoption of electric vehicles and renewable energy storage solutions. Industry leaders must start investing early in scalable and sustainable extraction technologies to gain a competitive edge in this market.

To get a deeper understanding of these technologies and their commercial viability, use Slate, an advanced research and patent analysis tool designed by GreyB.