Maintaining product integrity, increasing shelf life, and preventing contamination are some of the crucial problems various industries tackle today, especially the food and pharma sectors.

Evidently, the ongoing innovations within these industries focus on efficient temperature-controlled packaging solutions and materials.

While the Asia-Pacific region has shown remarkable growth in insulated packaging, our comprehensive report discusses other geographical areas with the highest growth rates.

Get the exclusive Packaging Industry Trends 2025 Report by filling out the form below:

This article explores the recent developments in thermal packaging and discovers the companies that are innovating in this domain.

What are the recent developments in Thermal Packaging?

Patent filings indicate this trend is particularly evident in the food and pharmaceutical sectors. Notably, 67% of patents in thermal insulation packaging focus on the food and beverage sector, whereas the pharmaceutical and medical domain accounts for 30% of the patents, further emphasizing the importance of insulated packaging in these sectors.

Let’s look at some of the developments in these sectors

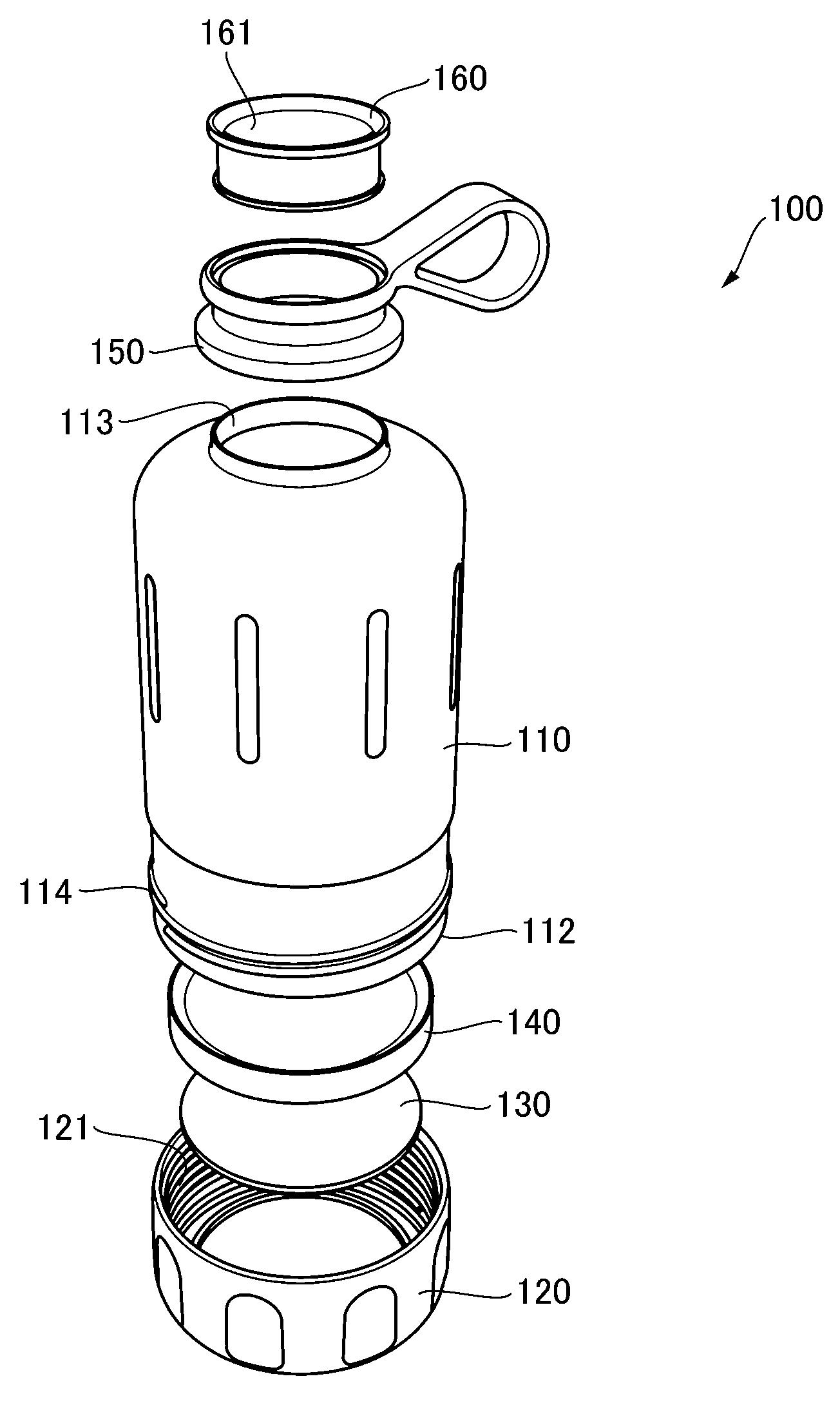

PET bottle cover with vacuum insulation

Pearl Metal company in Japan is developing a PET bottle cover (JP2022165327A)with a vacuum insulation structure to retain heat, allowing beverages to stay warm for extended periods. The design features an exposed spout and a second opening that exposes the bottle’s mouthpiece.

The bottom of the cover is attachable and detachable from the main opening, and a vacuum extends from the PET bottle’s side surface over to the drinking mouth.

This innovative configuration effectively enables PET bottles to maintain the temperature of hot beverages for prolonged durations.

Container that controls the beverage’s temperature

Novelis Incorporation, headquartered in the USA, is currently developing an aluminum beverage can (WO2022217216A1) that can control the temperature of the beverage it contains.

This is accomplished by using a configuration consisting of a beverage container with a container body and end. The container body includes an outer and inner wall, creating both an outer and inner cavity with an opening at the top end of the container body.

The inner wall is positioned within the outer cavity, creating a space between the top and bottom ends of the container body. This results in thermal insulation that aids in temperature regulation. Further, the top of the body attaches to the container end, which covers the opening of the inner cavity.

As a result, this arrangement of the outer and inner walls reduces thermal conductivity, effectively controlling the beverage’s temperature.

Who else is working on Thermal Packaging?

Significant Collaborations in Thermal Packaging

Additionally, we observed many cross-industry collaborations in the domain of thermal packaging. Some of these notable collaborations were between –

SOFRIGAM & CATHAY PACIFIC

Sofrigram, a French packaging company, collaborated with Cathay Pacific, an international airline, to integrate intelligent temperature logging systems for the swift and secure transportation of highly temperature-sensitive COVID-19 vaccines.

Cold Chain Technologies & B Medical Systems

Cold Chain Technologies, a packaging firm based in the United States, joined forces with B Medical Systems, a global manufacturer and distributor of medical-grade devices,to provide comprehensive thermal packaging and stationary refrigeration solutions specifically designed for temperature-critical applications.

Discover other cross-industry collaborations and innovations in thermal packaging in our exhaustive packaging report. Just fill out the form, and we’ll get the report directly to your inbox:

Is the focus on thermal insulation packaging moving towards recycling?

According to patent publications in this field, approximately 60% of the patents filed discuss enhancing recycling capabilities.

This surge in recycling-focused innovations can be attributed to the growing demand for sustainable solutions and the global effort to combat pollution caused by the packaging industry.

Let’s explore the recent advancements in this area:

Smurfit Kappa collaborates with Mindful Chef on recyclable insulation packs

Smurfit Kappa, a prominent packaging company based in Ireland, has joined forces with Mindful Chef, a meal kit retailer in London, to create recyclable corrugated cardboard insulation packs.

As verified by Smurfit Kappa’s Experience Centre, the insulation pack is entirely recyclable, meeting sustainability goals. Moreover, this innovative solution effectively sustains the required temperatures for an extended duration (maintaining temperatures below 8°C for over 30 hours) while reducing the carbon footprint by 30% compared to previous packaging alternatives.

Conclusion

With its innovative approach, strong emphasis on sustainability, and industry collaborations, thermal packaging offers enhanced convenience and peace of mind for manufacturers, distributors, and end users and helps with efficient product transportation and preservation.

Therefore, by prioritizing eco-friendly practices, thermal packaging minimizes resource consumption and fosters environmental responsibility. As a result, thermal packaging propels a more sustainable and responsible paradigm for product transportation and preservation, paving the way toward a greener future.

Authored By: Ambuj, Navjit, and Sushant, Patent Intelligence

Edited By: Ridhima, Marketing

Also Read: Smart, Green, and Lean: How Packaging Will Transform in 2025

Next Read: Innovative materials changing the Face of Thermal Insulation Packaging.