Sustainability trends in the tobacco industry are gaining attention. Swift advancements from filters that biodegrade within months to genetically optimized crops are transforming what’s possible in tobacco production.

Additionally, innovations in flavor release for pre-rolled cones and improved hookah designs enhance the smoking experience. Heat-not-burn devices offer better heating and flavor delivery for a more enjoyable and customizable experience.

This cover report briefly explores five trends, discussing important highlights of the solutions invented. But the full report comprehensively covers the ten most prominent trends in the tobacco industry in 2025, including:

- Novel organic fertilizers to enhance tobacco production

- New hookah designs for better smoke control

- Scope of data sharing in electronic cigarettes

- Age and user authentication methods for e-cigarettes

And more! Request the Tobacco report by filling out the form below:

Trend 1: Modifying tobacco plant genes to resist pests and boost yields

Gene modification techniques improve a plant’s tolerance for harsh atmospheric conditions and make it less susceptible to viruses and pests. These modifications reduce pesticide use while improving crop yield and quality and preventing the transfer of undesired characteristics.

Enhancing resistance against salinity, drought, and heat

| Innovation | Improving stability and reducing gene flow of tobacco using transgenes from Digitalis |

| Market Potential | Enhances plant resistance, phytoremediation, and production of valuable biopharmaceuticals and biofuels. |

| Application | Applied in enhancing plant resistance, environmental clean-up, making vaccines, and industrial enzymes. |

Tobacco and other plants are difficult to grow in hot areas that are dry and contain high levels. Gene modification enables plants to be grown in areas with such extreme conditions.

Key highlights:

- Researchers from BAİBÜ and Kastamonu University use chloroplast transformation to transfer transgenes from the Digitalis plant into tobacco.

- The method improves plant resistance to environmental stresses such as salinity, drought, and heat.

- It leverages homologous recombination to minimize risks like gene silencing and unintentional gene flow through pollen.

- The breakthrough has applications in phytoremediation, biopharmaceuticals, and industrial enzyme production.

Identifying genes resistant to tobacco spotted wilt disease (TSWD)

| Innovation | A new method to identify TSWD-resistant tobacco plants using molecular markers. |

| Market Potential | Supports sustainable agriculture by offering cost-effective disease resistance without the drawbacks of genetic linkage. |

| Application | Enhances breeding of tobacco plants resistant to TSWD while maintaining desirable growth and fertility traits. |

Spotted wilt, a disease caused by Orthotospoviruses, causes dwarfing and shrunken leaves in tobacco plants. It causes $1 billion in tobacco crop losses worldwide annually.

Key Highlights:

- Yunnan Tobacco Agricultural Sciences Research Institute can identify and select tobacco plants resistant to TSWD.

- These selections will not introduce undesirable traits like growth retardation and leaf deformities.

- Specific biomarkers help find plants with undesirable traits.

- It aligns with green preventive agricultural approaches, providing a sustainable and cost-effective tobacco plant disease management solution.

Trend 2: Variable HNB heating systems that outperform traditional methods

Recent trends in heating method innovations in the tobacco industry focus on optimizing heating efficiency. This ensures even heat distribution while maintaining the quality and safety of the aerosol produced. These advancements are essential for improving the functionality and user satisfaction of HNB products.

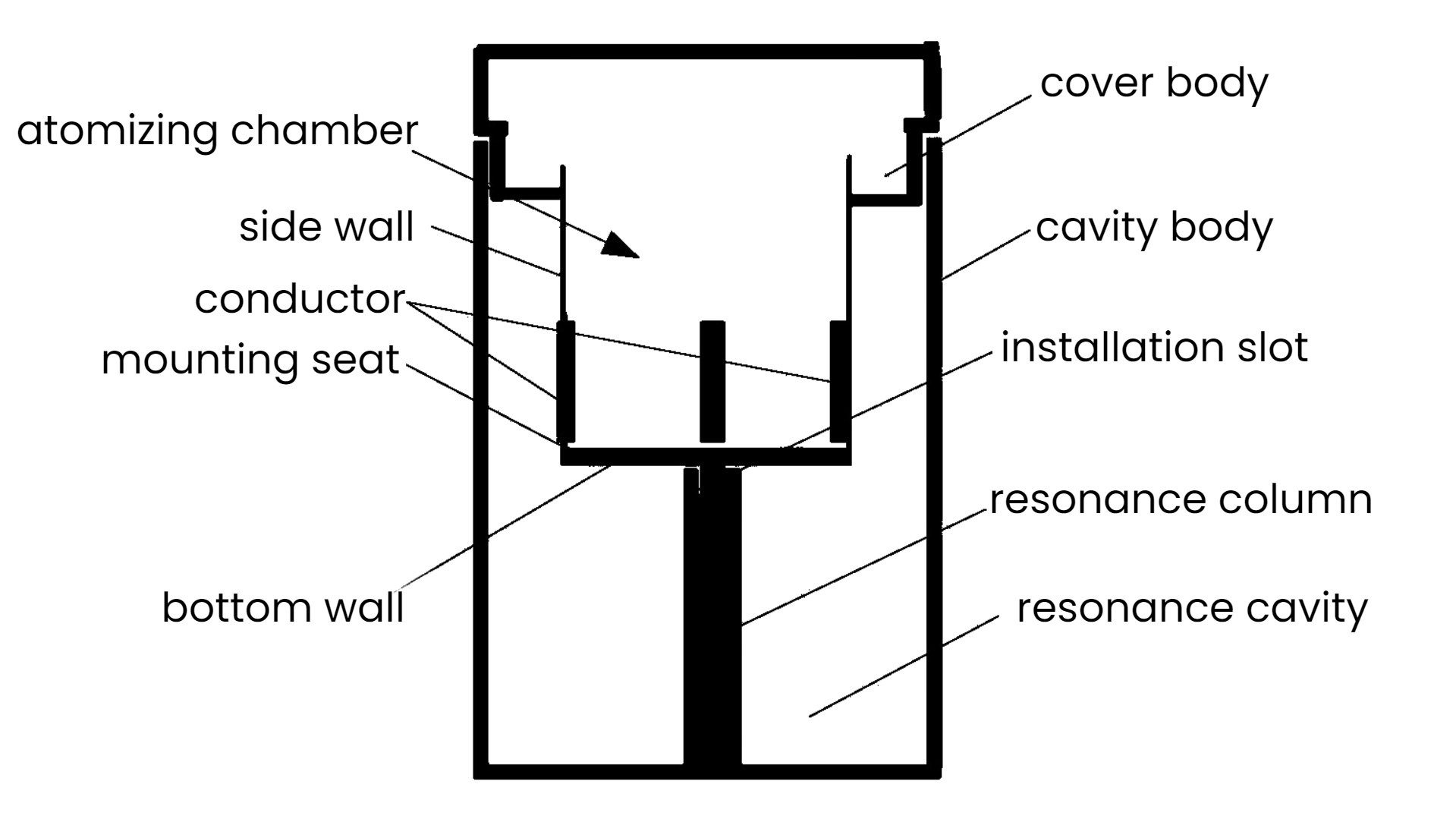

Variable-strength microwave heating for uniform combustion

| Innovation | A bio-organic fertilizer with a specific formulation for a fast and short-acting effect tailored to tobacco growth. |

| Market Potential | Provides a rapid nutrient solution to meet tobacco’s unique nutritional needs. |

| Application | Enhances tobacco growth by offering a quick nutrient release, increasing tobacco yield and quality. |

A challenge in current HNB devices using microwave heating is the uneven heating of the aerosol-generating substrate. Shenzhen Maxwell Technology created a solution by varying the microwave field strength at different positions within the atomizing chamber. This ensures uniform heating and improves user experience.

Achieving uniform heating with a dual-portion heating element

| Innovation | Specially designed HNB device addressing uneven heating |

| Market Potential | High potential in the growing HNB market as consumers and regulators shift away from traditional cigarettes |

| Application | It is used to enhance user experience and efficiency. |

RAI, owned by British American Tobacco (or BAT), has innovated an HNB device that solves the problem of uneven heating. This device’s design addresses uneven heating by ensuring that the outer surface and the inner channel of the aerosol-generating element receive consistent heat, significantly improving the efficiency and consistency of the produced aerosol.

Trend 3: New flavor release mechanisms for better taste and aroma in HNBs

Unlike traditional cigarettes, whose aroma is derived from a blend of leaf formulas, HNB devices rely on heating and airflow mechanisms to ensure stable and enjoyable flavor experiences. Innovation trends in flavor release in the tobacco industry include control systems and design changes for consistent airflow.

A varied-heating system to control aroma release in HNB devices

| Innovation | A device that controls the release of aroma using two heaters for steady smoke and scent production. |

| Market Potential | Easy to market because people want better-tasting aerosol products, especially in the tobacco market. |

| Application | Used in tobacco devices to improve aroma and flavor. |

China National Tobacco Corporation, Zhengzhou Tobacco Research Institute, and Yunnan China Tobacco Industry have collaborated and developed a solution to address these aroma issues.

Key highlights:

- The device uses a matrix and fragrance carrier to control aroma release.

- Two heating elements work at different temperatures for steady aerosol and fragrance production.

- The design improves the taste and quality of aerosol products.

Consistent aroma diffusion in HNB devices using a cigarette cup

| Innovation | A new aerosol system with a cigarette cup, smoking section, and airflow channels to improve aroma diffusion. |

| Market Potential | Ideal for consumers who seek consistent smoke and aroma in Heat-Not-Burn devices. |

| Application | Used in Heat-Not-Burn devices to provide more even smoke distribution and better aroma. |

In HNBs with oxygen-depleted heating, the lack of airflow through the tobacco confines smoke in the smoking section. This results in inconsistent aroma diffusion compared to conventional heated cigarettes. To address this problem, China National Tobacco Corporation, Zhengzhou Tobacco Research Institute, and Henan China Tobacco Industrial Co., Ltd. have collaboratively developed a novel aerosol generation system.

Key highlights:

- The system has a cigarette cup, a smoking section, and airflow channels to improve smoke movement.

- A clamping mechanism holds the product in place for stable airflow.

- The system balances air pressure to distribute aroma evenly across the aerosol.

Trend 4: Improving lyocell performance in biodegradable cigarette filters

Lyocell fiber-based cigarette filters present a biodegradable and sustainable alternative to traditional cellulose acetate filters. Recent Lyocell innovation trends have birthed filters optimized for improved smoke production, color consistency, and hardness, further enhancing their viability in the tobacco industry.

Lyocell filters with humectant for enhanced smoke production

| Innovation | A new Lyocell fiber filter that absorbs moisturizers faster and remains effective at high temperatures. |

| Market Potential | It improves smoke production, a key factor for consumer satisfaction in the cigarette industry. |

| Application | Used in cigarette filters to provide better smoke production and enhance user experience. |

Adding humectants (moisturizers) to cigarette filters enhances smoke production. However, traditional cellulose acetate filters are incompatible with moisturizers. Paper-based alternative filters suffer off-flavor and odor, among other issues.

KT&G and Kolon Industries have collaborated to develop a novel solution to improve cigarette filters.

Key highlights:

- Lyocell absorbs moisturizers faster than paper and works at temperatures above 300°C.

- The filter uses a mixture of propylene glycol, glycerine, and a binder for stability.

Improving the whiteness level of lyocell-based filters.

| Innovation | A process for achieving required whiteness levels in Lyocell fibers using a special treatment method. |

| Market Potential | It meets the cigarette manufacturers’ demand for fibers with specific whiteness levels for their filters. |

| Application | Used in cigarette filters to maintain the required visual standards while using Lyocell fibers. |

Cigarette filters require a certain whiteness level, but Lyocell fibers can’t use TiO2 like traditional filters. TiO2 is incompatible with Lyocell, and suitable alternatives were not available. KT&G and Kolon Industries have designed a method to achieve whiteness levels in Lyocell filters that are comparable to or exceeding traditional filters.

Key highlights:

- The process involves spinning Lyocell with cellulose pulp and Methyl Morpholine to form a multifilament.

- The multifilament is washed and treated to achieve the desired whiteness and yellowness before drying.

Trend 5: Simplifying custom flavor inserts for pre-rolled cones

Traditional hand-rolled cigarettes, cigars, and cigarillos often lack incorporated filters and flavoring mechanisms. This drawback brings up user safety and customization challenges. Recent innovations focus on integrating flavor-releasing mechanisms and improving filter materials. These designs make smokables safer, more efficient, and customizable.

Using flavor-releasing “click balls” as smokable inserts

| Innovation | A cost-effective smokable insert with compartments to securely hold flavor-releasing “click balls.” |

| Market Potential | Simplifies manufacturing and cuts costs, meeting rising consumer demand for flavor-enhanced smokable products. |

| Application | Used in smokable items to provide easy-to-use flavor-releasing mechanisms. |

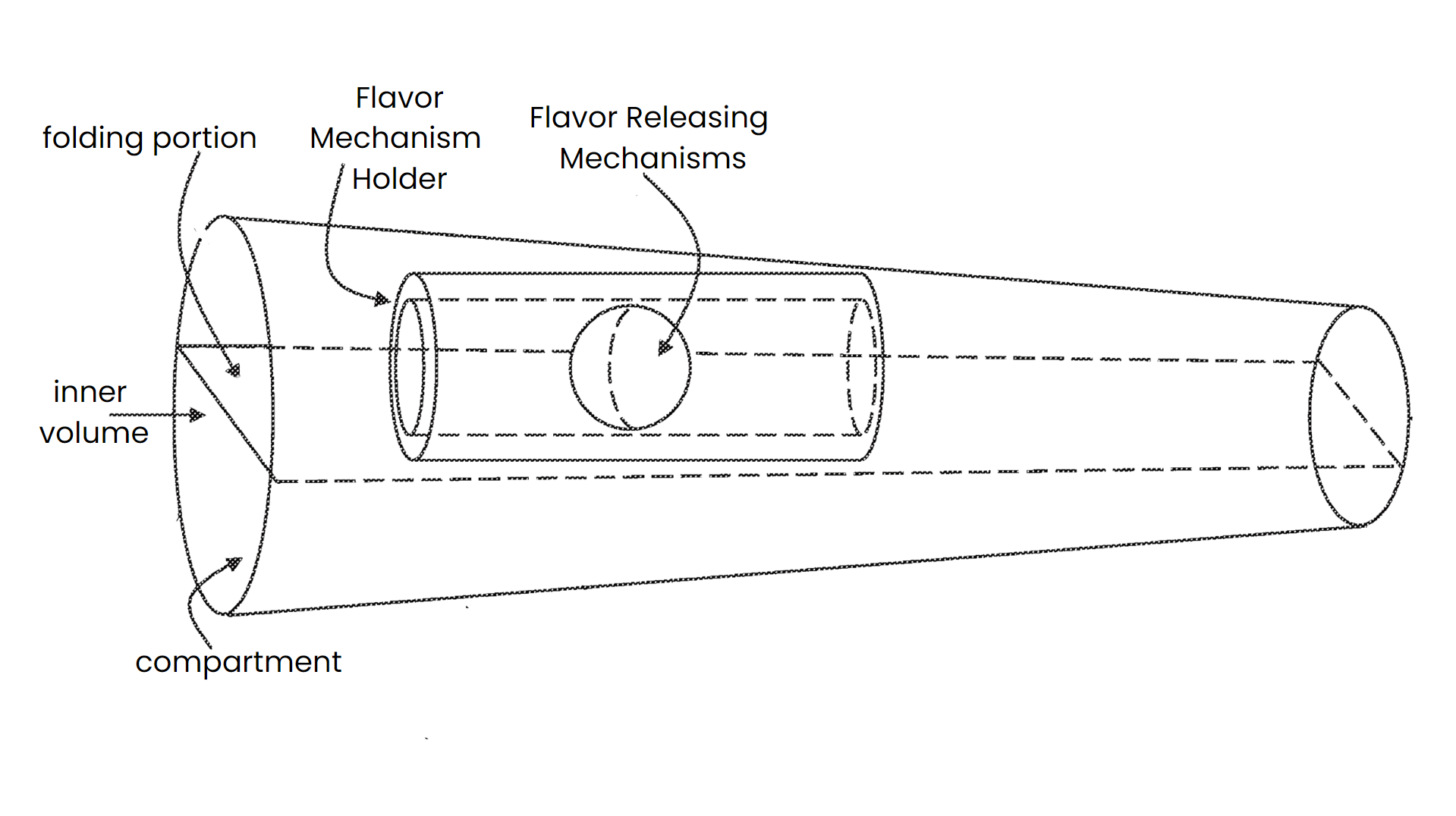

A new smokable industry trend involves incorporating flavor-releasing mechanisms within smokable inserts.

Aidemar Group developed a cost-effective insert system to house flavor-releasing mechanisms in smokable items securely.

Key highlights:

- The insert features a rolled material with open ends, creating two compartments separated by a partition.

- One compartment holds the flavor-releasing mechanism in place using friction.

- This design helps simplify production and lower costs

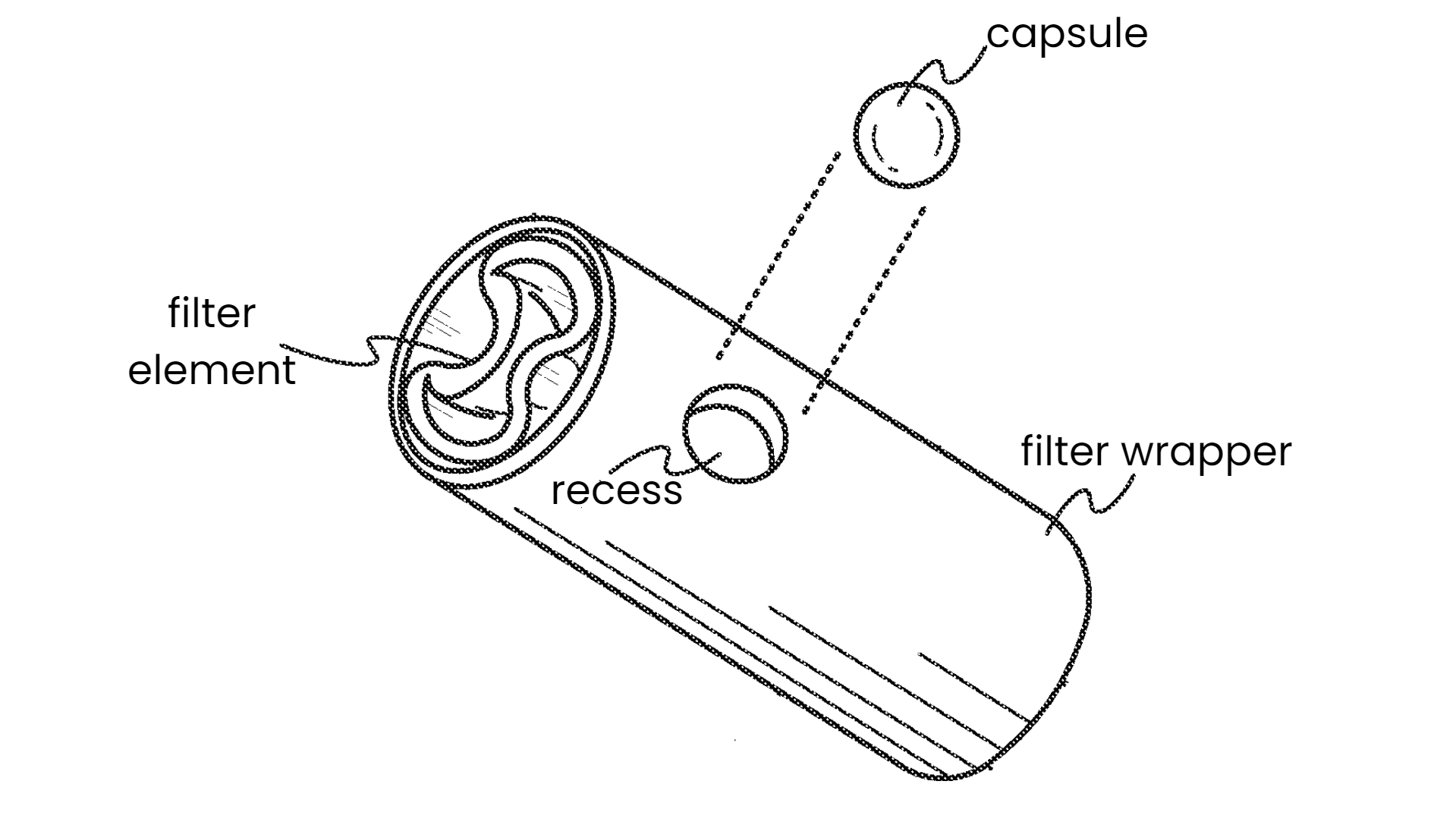

Filter made from natural materials having a shaped rim structure with a flavor capsule

| Innovation | A natural filter with a flavor capsule, allowing customization for hand-rolled smokables. |

| Market Potential | Meets the growing demand for eco-friendly, customizable smoking products. |

| Application | Used in hand-rolled cigarettes, cigars, and cigarillos to provide safer, customizable flavor options. |

Hand-rolled smokable filters are typically made from synthetic materials that pose health risks when burned. Adding flavors to hand-rolled smokables is difficult, limiting customization options. Good Tree International developed a hand-rolled smokable filter incorporating a flavoring capsule.

Key highlights:

- The filter body includes a cavity where the flavor capsule is securely placed.

- The filter can be made from natural materials like corn husk, rice paper, and hemp paper, offering an eco-friendly alternative.

- Crushing the capsule releases the flavor, allowing users to customize their smoking experience.

Download the Tobacco Innovation Trends 2025 report to access five more trends that will change the tobacco industry landscape. Fill out the form below to get the report delivered directly to your inbox.\

The Path Forward

In 2025, the tobacco industry will focus on specialized products for consumer needs. This includes biodegradable filter cigarettes for environmentally conscious users and low-nicotine options to reduce dependency. Innovations like e-cigarettes, Heat-Not-Burn devices, and improved hookahs will enhance user experience while lowering environmental impact. Companies that quickly adapt to these industry trends will dominate the evolving tobacco market.

Partnering with an R&D expert ensures you uncover growth opportunities, safeguard your IP, and stay ahead in the tobacco industry. Gaining deep expertise in technology scouting, competitive analysis, and market research empowers you to make informed decisions confidently.

GreyB uncovers valuable opportunities for your business in the tobacco industry with actionable strategies tailored to your unique needs. Ensure your innovation efforts are protected and strategically aligned with the future. Reach out to explore how we can collaborate on your next big move.

How Can We Help You?

We support industry-leading R&D and Innovation professionals through complex problems. Describe your challenge, and let us bring clarity and expertise.